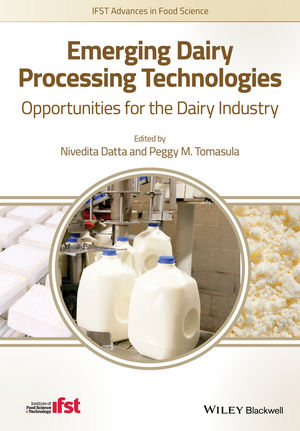

Emerging Dairy Processing Technologies

Wiley-Blackwell (Verlag)

978-1-118-56062-4 (ISBN)

- Titel z.Zt. nicht lieferbar

- Versandkostenfrei innerhalb Deutschlands

- Auch auf Rechnung

- Verfügbarkeit in der Filiale vor Ort prüfen

- Artikel merken

Dr Nivedita Datta is a Lecturer in Food Science and Technology in the College of Health and Biomedicine at Victoria University, Melbourne, Australia. Dr Peggy M. Tomasula is Research Leader of the Dairy and Functional Foods Research Unit (DFFRU) at USDA/ARS/ERRC in Wyndmoor, Pennsylvania, USA.

About the IFST Advances in Food Science Book Series xi List of Contributors xiii

Preface xv

1 Crossflow Microfiltration in the Dairy Industry 1

Peggy M. Tomasula and Laetitia M. Bonnaillie

1.1 Introduction 1

1.1.1 Membrane Types 1

1.1.2 MF Membranes 3

1.1.3 Pilot Plant Testing 6

1.2 MF Principles and Models 8

1.2.1 Gel Polarization Models 10

1.2.2 Osmotic Pressure Model 11

1.2.3 Resistance–in-Series Model 12

1.3 Applications of MF 13

1.3.1 Production of Concentrated Micellar Casein and Whey Proteins 13

1.3.2 Extended Shelf Life Milk 15

1.3.3 Cold Processing MF of Milk 20

1.3.4 Separation and Fractionation of Milk Fat from Whole Milk or Buttermilk 21

1.3.5 Separation of Milk Bioactive Compounds 22

1.3.6 Other Applications 23

1.4 Membrane Modifications to Increase Performance 23

1.5 Microsieves 23

1.6 Conclusions 24

Acknowledgements 25

Disclaimer 25

References 25

2 Novel Thermal Methods in Dairy Processing 33

Vijay K. Mishra and Lata Ramchandran

2.1 Introduction 33

2.2 Ohmic Heating 36

2.2.1 Principles 37

2.2.2 Factors Affecting OH 37

2.2.3 Applications and Influence of OH on Dairy Product Quality 40

2.3 Microwave Heating (MWH) and Radio Frequency Heating (RFH) 42

2.3.1 Principles 43

2.3.2 Factors Affecting MWH and RFH 44

2.3.3 Applications and Influence on Quality of Milk and Milk Products 48

2.4 Aspects of Microbiological Safety of Dairy Products 55

2.5 Conclusions 60

References 61

3 High-Pressure Processing of Milk and Dairy Products 71

Daniela D. Voigt, Alan L. Kelly, and Thom Huppertz

3.1 Introduction to High-Pressure Processing 71

3.2 Effects of High Pressure on Food Constituents: Basic Considerations 74

3.3 Effects of High Pressure on the Constituents of Milk 74

3.3.1 Milk Salts 74

3.3.2 Milk Fat and Milk Fat Globules 75

3.3.3 Whey Proteins 75

3.3.4 Casein Micelles 76

3.3.5 Milk Enzymes 77

3.3.6 Viscosity and Rheological Properties 78

3.4 Effects of High Pressure on Dairy Microbiology 78

3.5 HP Treatment and Cheese 79

3.6 High-Pressure Processing and Yoghurt 83

3.7 High-Pressure Processing and Functional Dairy Products 83

3.8 Ice Cream 84

3.9 Conclusions and Perspectives for the Dairy Industry 85

References 85

4 Applications of High-Pressure Homogenization and Microfluidization for Milk and Dairy Products 93

John Tobin, Sinead P. Heffernan, Daniel M. Mulvihill, Thom Huppertz, and Alan L. Kelly

4.1 Introduction 93

4.2 Emulsion Stability and Instability 94

4.2.1 Effects of Homogenization 94

4.2.2 Principles of High-Pressure Homogenization 96

4.2.3 Microfluidization 98

4.3 Effects of High-Pressure Homogenization and Microfluidization on Milk Constituents 99

4.3.1 Milk Fat Globules 99

4.3.2 Milk Proteins 101

4.3.3 Milk Enzymes 102

4.3.4 Microorganisms 103

4.4 Applications of HPH and Microfluidization in the Manufacture of Dairy Products 103

4.4.1 Milk 103

4.4.2 Yoghurt Manufacture 104

4.4.3 Cheese 105

4.4.4 Ice Cream 106

4.4.5 Cream Liqueurs 107

4.5 Conclusions and Future Perspectives 108

References 108

5 Pulsed Electric Fields (PEF) Processing of Milk and Dairy Products 115

Fernando Sampedro and Dolores Rodrigo

5.1 Introduction 115

5.1.1 Technology Principles 115

5.1.2 Processing Equipment 117

5.2 Application of PEF for Milk Pasteurization 118

5.2.1 Microbiological Aspects 118

5.2.2 Quality Aspects 125

5.2.3 Bioactive Compounds 128

5.2.4 Shelf Life Extension 128

5.3 Application of PEF to Dairy Products 130

5.3.1 Fruit Juice–Milk Beverages 130

5.3.2 Soya Milk and Fruit Juice–Soya Milk Beverages 137

5.3.3 Yogurt-Based Beverages 138

5.3.4 Infant Formula Milk Beverages 138

5.3.5 Other Milk-Based Beverages 139

5.4 Commercial Applications of PEF for Milk Pasteurization 140

5.5 Conclusions 141

References 141

6 High Power Ultrasound Processing in Milk and Dairy Products 149

Bogdan Zisu and Jayani Chandrapala

6.1 Introduction: Ultrasound in Dairy 149

6.2 Ultrasonic Equipment 151

6.3 Effects of Sonication on Milk Fat: Homogenization and Creaming 152

6.3.1 Homogenization 152

6.3.2 Creaming 155

6.4 Degassing and Foam Reduction 155

6.5 Thermosonication to Reduce Microbial Load 156

6.6 Ultrasound Assisted Filtration 157

6.7 Sonocrystallization of Lactose from Whey 159

6.8 Solubility of Rehydrated Powders 161

6.9 Effects of sonication on Milk and Casein Systems 163

6.9.1 Effects of Sonication on the Casein Micelle 163

6.9.2 Applied Ultrasound to Control the Viscosity of Milk Concentrates 164

6.10 Effects of Sonication on the Physical and Functional Properties of Whey Proteins 167

6.10.1 Gelation and Viscosity 167

6.10.2 Understanding Whey Protein Changes Induced by Ultrasound 169

6.10.3 Heat Stability of Whey Proteins 169

6.11 Sensory Characteristics of Sonicated Milk and Whey 172

6.12 Conclusions 173

References 173

7 Ultraviolet and Pulsed Light Technologies in Dairy Processing 181

Nivedita Datta, Poornimaa Harimurugan, and Enzo A. Palombo

7.1 Introduction 181

7.2 Basic Principles of UV Processing 183

7.2.1 The UV Process 183

7.3 Available UV Treatment Equipment and Their Operation 185

7.3.1 UV Dose Determination 187

7.3.2 UV Dose Measurement 188

7.4 Effects of UV Treatment on Microorganisms 188

7.4.1 Mechanisms of Action 188

7.4.2 Inactivation of Bacteria in Milk and Dairy Products 189

7.4.3 Packaging and Surface Disinfection 192

7.5 Commercial Developments 192

7.6 Other Light Processing Technique using UV light 194

7.7 Basic Principle of PL Technology 195

7.8 Effects of PL on Microorganisms 196

7.8.1 Mechanisms of Action 196

7.8.2 Inactivation of Bacteria in Liquid and Dairy Products 196

7.9 Commercial Developments 199

7.10 Conclusions 199

Acknowledgements 200

References 200

8 Carbon Dioxide: An Alternative Processing Method for Milk 205

Laetitia M. Bonnaillie and Peggy M. Tomasula

8.1 Introduction 205

8.2 Physicochemical Principles 206

8.2.1 Solubility of CO2 in Aqueous Solutions 207

8.2.2 Solubility of CO2 in Milk 208

8.3 Microbiological Action of High-Pressure and Supercritical CO2 209

8.3.1 Mechanism of Action of CO2 209

8.3.2 Influence of Processing Parameters: T, P, Agitation and Time 211

8.3.3 Inactivation of Different Microorganisms with CO2 211

8.3.4 Kinetics of Bacterial Inactivation with CO2 223

8.4 High-Pressure CO2 Treatment of Milk and Dairy Foods 223

8.4.1 Microbial Flora of Raw and Pasteurized Milk 223

8.4.2 Food Composition Affects the Bactericidal Action of CO2 225

8.4.3 Treatment of Milk with High-Pressure CO2 226

8.5 Low-Pressure CO2 Injection (Carbonation) to Extend the Shelf Life of Fluid Milk and Soft Dairy Products 228

8.5.1 Advantages of Carbonation 228

8.5.2 Does CO2 Treatment Affect the Quality and Functionality of Dairy Products? 229

8.5.3 Carbonated Raw Milk 230

8.5.4 Carbonated Pasteurized Milk 231

8.5.5 Cottage Cheese 232

8.5.6 Yogurt 233

8.5.7 Fermented and Flavoured Dairy Beverages 233

8.5.8 Butter, Sour Cream and Ice Cream 234

8.6 Other Dairy-Related Applications for CO2 234

8.6.1 Fractionation of Milk Lipids 234

8.6.2 Manufacture of Cheese from CO2-Treated Milk 236

8.6.3 Fractionation of Milk Proteins 237

8.7 Regulatory Status 239

Acknowledgements 240

References 240

9 Non-Thermal Pasteurization of Milk Using CHIEF Technology 251

Shaobo Deng, Paul Chen, Yun Li, Xiaochen Ma, Yanling Cheng, Xiangyang Lin, Lloyd Metzger, and Roger Ruan

9.1 Introduction 251

9.2 Principles 252

9.2.1 Biological Effects 252

9.2.2 Physical Principles 252

9.3 Equipment and Process Flow 255

9.4 Effects of the Process on Microorganisms and Quality 258

9.4.1 Microorganisms 258

9.4.2 Quality 259

9.5 Other Uses of CHIEF Technology 261

9.6 Future Development 261

9.6.1 Hardware Development 262

9.6.2 Evaluation of the Process 262

9.6.3 Hurdle Technology 262

Acknowledgements 263

References 263

10 Bacteriocins of Food Grade Lactic Acid Bacteria in Hurdle Technology for Milk and Dairy Products 267

John A. Renye, Jr and George A. Somkuti

10.1 Introduction 267

10.2 Bacteriocin Structure and Production 268

10.3 Application of Bacteriocins in Dairy Foods 273

10.3.1 Applications to Improve Food Safety 274

10.3.2 Sensory Effects of Bacteriocin Applications 275

10.3.3 Bacteriocin Resistance 276

10.4 Bacteriocins as Components of Hurdle Technology 277

10.4.1 Combined with Conventional Treatments 277

10.4.2 Combined with Emerging Technologies 280

10.5 Bacteriocins in Hurdle Technology for Dairy Food Safety 281

10.5.1 Bacteriocins Combined with Temperature Regulation 281

10.5.2 Bacteriocins Combined with Other Natural Preservatives 285

10.5.3 Bacteriocins and Pulsed Electric Fields 287

10.5.4 Bacteriocins and High-Pressure Processing 288

10.6 Conclusions 289

References 290

11 Leveraging the Beneficial Compounds of Organic and Pasture Milk 307

Michael H. Tunick, Diane L. Van Hekken, and Moushumi Paul

11.1 Introduction 307

11.2 Regulatory Status 307

11.2.1 Organic and Conventional Dairies 307

11.2.2 Nutritional claims 308

11.3 Bioactive Compounds in Milk 311

11.3.1 Peptides and Proteins 311

11.3.2 Fatty Acids 313

11.3.3 Vitamins and Minerals 314

11.4 Variations in Biologically Active Compounds 319

11.4.1 Pasture, Organic and Conventional Milk 319

11.4.2 Pasteurization and Homogenization 319

11.4.3 Feed Changes 320

11.5 The Future 321

11.5.1 Trends 321

11.5.2 Goals and Research Needs 322

Disclaimer 322

References 322

Index 333

| Erscheint lt. Verlag | 22.6.2015 |

|---|---|

| Reihe/Serie | IFST Advances in Food Science |

| Verlagsort | Hoboken |

| Sprache | englisch |

| Maße | 175 x 252 mm |

| Gewicht | 848 g |

| Themenwelt | Technik ► Lebensmitteltechnologie |

| Weitere Fachgebiete ► Land- / Forstwirtschaft / Fischerei | |

| ISBN-10 | 1-118-56062-0 / 1118560620 |

| ISBN-13 | 978-1-118-56062-4 / 9781118560624 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich