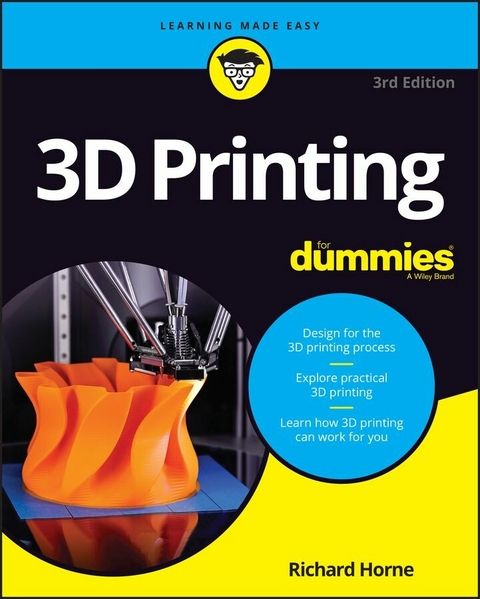

3D Printing For Dummies (eBook)

416 Seiten

John Wiley & Sons (Verlag)

978-1-394-16949-8 (ISBN)

3D Printing For Dummies is an easy reference for anyone new to the process of taking a digital file and turning it into an object in the real world. (Pretty amazing stuff, right?) It's also a handy guide for more experienced users looking to learn the latest and greatest in additive manufacturing. Updated for the latest generation of machines and materials, this book walks you through creating models and printing 3D objects. You'll get the scoop on the impact of these versatile machines in production and manufacturing, reuse and recycling, intellectual property design controls, and more. It's an exciting time to get into 3D printing, and this friendly Dummies guide is here to help you do it.

* Wrap your mind around the technology of 3D printing

* Understand how 3D printing is transforming industries

* Get an intro to making your own digital models

* Consider the pros and cons of 3D printing for your hobby or business needs

3D Printing For Dummies is a perfect resource for anyone interested in learning about and taking advantage of 3D printing technology.

Richard Horne is an electronics engineer, product designer, technical salesman, and problem solver with more than 30 years of experience and innovation across industries. Known in the community as RichRap, his blog makes 3D printing easier for everyone to understand.

Introduction 1

Part 1: Getting Started with 3D Printing 5

Chapter 1: Seeing How 3D Printers Fit into Modern Manufacturing 7

Chapter 2: Exploring the Types of 3D Printing 19

Chapter 3: Exploring Applications of 3D Printing 31

Part 2: Outlining 3D-Printing Resources 47

Chapter 4: Identifying Available Materials for 3D Printing 49

Chapter 5: Identifying Sources and Communities for 3D-Printable Objects 67

Part 3: Exploring the Business Side of 3D Printing 83

Chapter 6: 3D Printing for Everyone 85

Chapter 7: Understanding 3D Printing's Effect on Traditional Lines of Business 97

Chapter 8: Reviewing 3D-Printing Research 107

Part 4: Employing Personal 3D-Printing Devices 119

Chapter 9: Exploring 3D-Printed Artwork 121

Chapter 10: Considering Consumer-Level Desktop 3D Printers 129

Chapter 11: Deciding on a 3D Printer of Your Own 157

Part 5: Understanding and Using Your 3D Printer 197

Chapter 12: Assembling Kits and Reviewing Machine Setup 199

Chapter 13: Understanding 3D Printer Control Electronics 219

Chapter 14: Understanding, Using, and Servicing 3D Printers 251

Chapter 15: Identifying Software and Calibrating Your 3D Printer 293

Chapter 16: Refining the Design and 3D-Printing Process 337

Part 6: The Part of Tens 371

Chapter 17: Ten Examples of Direct Digital Manufacturing and Personalization 373

Chapter 18: Ten Impossible Designs Created Using Additive Manufacturing 379

Index 385

| Erscheint lt. Verlag | 5.9.2023 |

|---|---|

| Sprache | englisch |

| Themenwelt | Informatik ► Weitere Themen ► Hardware |

| Schlagworte | 3D-Druck • 3D-Drucker • Computer Peripherals (printers,modems,scanners,etc.) • Computer-Ratgeber • End-User Computing • Peripheriegeräte (Drucker, Scanner, Modems usw.) |

| ISBN-10 | 1-394-16949-3 / 1394169493 |

| ISBN-13 | 978-1-394-16949-8 / 9781394169498 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Größe: 87,6 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich