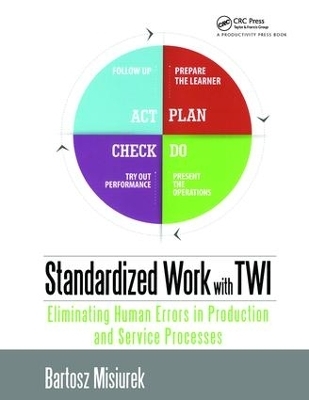

Standardized Work with TWI

Productivity Press (Verlag)

978-1-4987-3754-8 (ISBN)

Work standardization is not just the creation of job instructions-it is a comprehensive approach in which employees are formally trained and their skills in the area of work improvement are developed by kaizen sessions. With poor instructions, though, the effectiveness of these two key activities in the work standardization process is practically impossible to achieve. The book introduces you to 41 rules for standard work instruction (SWI) preparation. Following these rules will ensure that the instructions in your company are ideally suited to train operators and improve work. The author developed these rules based on his professional experience and practice within the TWI program in more than 120 manufacturing and service enterprises, while creating thousands of SWIs.

These rules are a clear set of signposts that will help you develop a correct SWI on the first attempt without any unnecessary correction of errors. The quality of SWIs significantly affects how on-the-job training sessions are run, as well as how work analysis with respect to improvement is conducted.

Bartosz Misiurek, PhD, first gained Lean implementation experience in the automotive and food industries. He then continued developing under the supervision of international experts Marek Piatkowski, a former director of Canadian Toyota, and Richard Abercrombie, a former Boeing manager and a consultant of the TWI Institute. Since 2007, he has been responsible at the Lean Enterprise Institute Poland for the transfer of the TWI program from the United States, and then for its development in Poland. He currently is the chief executive officer (CEO) at Leantrix Company, which among others provides computer systems that aid the implementation of TWI programs.

Introduction to the Work Standardization Process

What Is Work Standardization?

Human Errors: Are They a Problem at Your Workplace?

Work Standardization as an Effective Approach in the Elimination of Human Errors

Work Standardization: The Foundation of Lean Management and Training within Industry

The Role of the Leader in the Work Standardization Process

Production Process Documentation

Introduction

Descriptive Instructions

Introduction to the Preparation of SWI

41 Rules for SWI Preparation

Application of SWIs for Describing Various Operational Processes (TPM, SMED, Etc.)

Summary

Kaizen-Based Improvement of Production Processes

Kaizen: The Essence of Improvement

Genesis of the Kaizen-Based Improvement Approach

TWI JM Construction and the Importance of 5W1H

Problems in the Joint Application of TWI JM and TWI JI in Production Companies

The Poka Yoke Generator Sheet

Work Method Improvement Using the PYGS as Applied to the Example of Tying the Fire Underwriter’s Knot

System Kaizen and Kaizen Events

Summary

Training Workers

On-the-Job Training Methods

Typical Errors during On-the-Job Trainings in Production Companies

TWI JI Structure

The JBS as the Essential Element of the TWI JI-Based on-the-Job Trainings

TWI JI and the Most Common Mistakes during On-the-Job Trainings

TWI JI-Consistent Training Scenario of Tying the Fire Underwriter’s Knot

Summary of the Training on Tying the Fire Underwriter’s Knot

Estimating the Duration of On-the-Job Training

Calculation of the Estimated Instruction Time for Tying the Fire Underwriter’s Knot

TWI JI Application for Conveying Knowledge, Not Practical Skills: An Introduction to Method Instruction (MI)

Application of MI to Train the Learner on TWI JI

Summary

Work Standardization Process Implementation and Management

Step 1: Planning Work Standardization Implementation and Management (PLAN)

Step 2: Implementation of Work Standardization on Specific Operations of the Selected Pilot Areas (DO)

Step 3: Checking How the Implementation Leaders Apply Work Standardization in the Chosen Pilot Areas (CHECK)

Step 4: Maintaining the Work Standardization Process According to TWI (ACT)

Problems with Work Standardization Implementation

Practical Workshop Dedicated to Work Standardization According to the TWI Program

Preparation for Training

Summary

Afterword

References

| Erscheinungsdatum | 12.07.2016 |

|---|---|

| Zusatzinfo | 35 colour illustrations, 48 black & white tables |

| Verlagsort | Portland |

| Sprache | englisch |

| Maße | 216 x 279 mm |

| Gewicht | 614 g |

| Themenwelt | Technik |

| Wirtschaft ► Betriebswirtschaft / Management ► Personalwesen | |

| ISBN-10 | 1-4987-3754-4 / 1498737544 |

| ISBN-13 | 978-1-4987-3754-8 / 9781498737548 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich