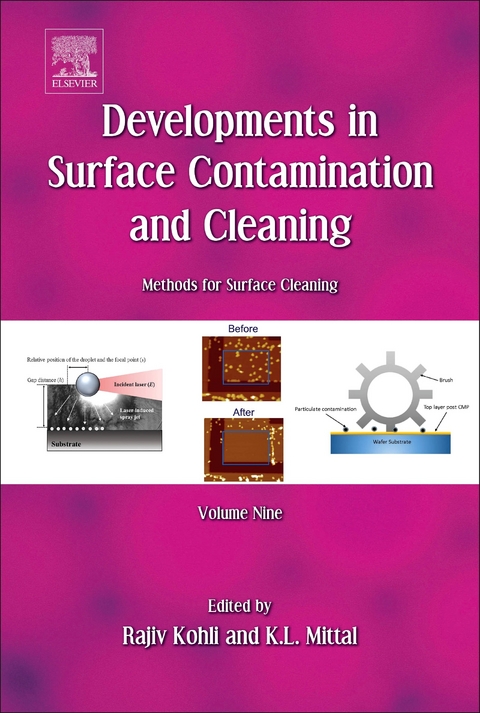

As device sizes in the semiconductor industries shrink, devices become more vulnerable to smaller contaminant particles, and most conventional cleaning techniques employed in the industry are not effective at smaller scales. The book series Developments in Surface Contamination and Cleaning as a whole provides an excellent source of information on these alternative cleaning techniques as well as methods for characterization and validation of surface contamination. Each volume has a particular topical focus, covering the key techniques and recent developments in the area. Several novel wet and dry surface cleaning methods are addressed in this Volume. Many of these methods have not been reviewed previously, or the previous reviews are dated. These methods are finding increasing commercial application and the information in this book will be of high value to the reader. Edited by the leading experts in small-scale particle surface contamination, cleaning and cleaning control these books will be an invaluable reference for researchers and engineers in R&D, manufacturing, quality control and procurement specification situated in a multitude of industries such as: aerospace, automotive, biomedical, defense, energy, manufacturing, microelectronics, optics and xerography.

- Provides a state-of-the-art survey and best-practice guidance for scientists and engineers engaged in surface cleaning or handling the consequences of surface contamination

- Addresses the continuing trends of shrinking device size and contamination vulnerability in a range of industries, spearheaded by the semiconductor industry and others

- Covers novel wet and dry surface cleaning methods of increasing commercial importance

As device sizes in the semiconductor industries shrink, devices become more vulnerable to smaller contaminant particles, and most conventional cleaning techniques employed in the industry are not effective at smaller scales. The book series Developments in Surface Contamination and Cleaning as a whole provides an excellent source of information on these alternative cleaning techniques as well as methods for characterization and validation of surface contamination. Each volume has a particular topical focus, covering the key techniques and recent developments in the area.Several novel wet and dry surface cleaning methods are addressed in this Volume. Many of these methods have not been reviewed previously, or the previous reviews are dated. These methods are finding increasing commercial application and the information in this book will be of high value to the reader. Edited by the leading experts in small-scale particle surface contamination, cleaning and cleaning control these books will be an invaluable reference for researchers and engineers in R&D, manufacturing, quality control and procurement specification situated in a multitude of industries such as: aerospace, automotive, biomedical, defense, energy, manufacturing, microelectronics, optics and xerography. Provides a state-of-the-art survey and best-practice guidance for scientists and engineers engaged in surface cleaning or handling the consequences of surface contamination Addresses the continuing trends of shrinking device size and contamination vulnerability in a range of industries, spearheaded by the semiconductor industry and others Covers novel wet and dry surface cleaning methods of increasing commercial importance

Front Cover 1

Developments in Surface Contamination and Cleaning: Cleaning Techniques 4

Copyright 5

Contents 6

Contributors 10

Preface 12

About the Editors 16

Chapter 1: How Green and Does it Clean: Methodologies for Assessing Cleaning Products for Safety and Performance 18

1. Background 19

2. Environmental Concerns 20

3. Green Cleaning 20

4. Regulatory Aspects 23

5. Product Selection 25

6. Green Assessment-What Makes a Product Green? 26

6.1. Pollution Prevention Options Assessment Tool (P2OASys) 27

6.2. Green Screen 28

6.2.1. Human Health Group I 33

6.2.2. Human Health Group II and II 33

6.2.3. Environmental Toxicity and Fate 33

6.2.4. Physical Hazards 33

6.2.5. Green Screen Process Steps 34

6.3. Environmental Protection Agency Design for the Environment 37

6.3.1. Acute Mammalian Toxicity 38

6.3.2. Carcinogenicity 38

6.3.3. Genetic Toxicity 38

6.3.4. Neurotoxicity 38

6.3.5. Repeated Dose Toxicity 38

6.3.6. Reproductive and Developmental Toxicity 38

6.3.7. Respiratory Sensitization 39

6.3.8. Skin Sensitization 39

6.3.9. Environmental Toxicity and Fate 39

6.3.10. Eutrophication 39

6.4. Green Seal Environmental Standard for Cleaning and Degreasing Agents (GS 34) 47

6.4.1. Toxic Compounds 47

6.4.2. Carcinogens and Reproductive Toxins 47

6.4.3. Corrosivity and Causticity 47

6.4.4. Skin and Eye Irritation 47

6.4.5. Flammability and Ignitability 47

6.4.6. VOC Content 48

6.4.7. Ozone Depletion 48

6.4.8. Toxicity to Aquatic Life 48

6.4.9. Aquatic Biodegradability 48

6.4.10. Eutrophication 48

6.4.11. Disposal 48

6.4.12. Animal Testing 48

6.5. Quick Guide for Tools 48

7. Performance Testing/Efficacy Evaluation 51

7.1. Basic Testing Process 53

7.1.1. Phase I Product Selection 53

7.1.2. Phase II Temperature and Concentration Studies 53

7.1.3. Phase III Mechanical Energy Studies 54

7.1.4. Phase IV Actual Product Cleaning Studies 55

7.1.5. Phase V Pilot Plant/Scale-Up Feasibility Studies 55

7.2. Case Studies 57

7.2.1. Case Study1-Shedding Some Light on Laboratory Versus Field Practices [22] 57

7.2.2. Case Study2-Thinking Outside the Cable Box-Wire & Cable Company Uses Floor Stripper on Cables [23]

7.2.3. Case Study3-A Gear Company Decides to Go all the ``Wayqueous´´-Greasing the Wheels for Regulatory Change and Resis... 77

7.3. Case Study Summary 80

8. Summary 80

Appendix A. Contact Information for Cleaning Products and Suppliers 81

Appendix B. Contact Information for Soils and Contaminants and Suppliers 84

References 85

Chapter 2: UV-Ozone Cleaning for Removal of Surface Contaminants 88

1. Introduction 88

2. Surface Contamination and Cleanliness Levels 89

3. Principles of UV-Ozone Cleaning 90

4. Process Variables 95

4.1. UV Sources 95

4.2. Distance from the Source 95

4.3. Precleaning 95

4.4. Types of Contaminants 96

4.5. Types of Substrates 96

5. Cleaning Systems 96

5.1. Costs 102

5.1.1. Examples of Cost Savings 102

6. Advantages and Disadvantages of UV-Ozone Cleaning 103

6.1. Advantages 103

6.2. Disadvantages 104

7. Applications 105

7.1. Semiconductor and Electronics Parts 106

7.2. Cleaning of Reference Masses 107

7.3. Solar Wind Sample Collectors 107

7.4. Metal Surfaces 107

7.5. Glass and Optical Materials 108

7.6. Probe Tips 109

7.7. Decontamination of Incubator Cabinets 109

7.8. Preparation of Samples for Trace Element Analysis 110

7.9. Polymer Surfaces 110

7.10. Textiles and Fabrics 111

8. Summary 111

References 85

Chapter 3: Use of Water Ice for Removal of Surface Contaminants 122

1. Introduction 122

2. Surface Contamination and Surface Cleanliness Levels 123

3. Theoretical Considerations 133

3.1. Phase Behavior 133

3.2. Mechanical Properties 134

3.3. Mechanism of Ice Blasting 136

4. Description of the Process 138

5. Cleaning Systems 139

5.1. Abrasive Medium Addition 143

6. Cost Considerations 143

7. Advantages and Disadvantages 145

7.1. Advantages 145

7.2. Disadvantages 145

8. Applications 146

8.1. Semiconductor Wafer Cleaning 146

8.2. Electronics and Photonics Applications 147

8.3. Automotive Components 147

8.4. Nuclear Applications 148

8.5. Deburring of Components 150

8.6. Recycling and Recovery 151

8.7. Facility Decommissioning 151

8.8. Restoration of Historic Building 151

8.9. Oil Field Equipment Cleaning 152

8.10. Cleaning Pipes 153

9. Summary and Conclusions 153

References 85

Chapter 4: Post-CMP Cleaning 162

1. Introduction 162

2. Forces on Particulate Contaminants in a Post-CMP Cleaning Process 164

2.1. van der Waals Forces 164

2.2. Double-Layer Interactions 167

3. Types of Post-CMP Cleaning Processes 168

3.1. Batch Cleaning 168

3.2. Single Wafer Cleaning 173

3.2.1. Brush Cleaning 173

4. Megasonic Cleaning 180

5. Cleaning Chemistries 186

5.1. Silicon Dioxide Post-CMP Cleaning 186

5.2. Tungsten Post-CMP Cleaning 191

5.3. Copper Post-CMP Cleaning 192

6. Summary 197

References 85

Chapter 5: A Brief Review of the Cleaning Process for Electronic Device Fabrication 202

1. Introduction 203

2. Cleaning of Inorganic Contamination 203

2.1. Neutral Particles 203

2.2. Ionically Bonded Particles 204

2.2.1. Ionic SRP 204

2.2.2. Ionic Trapping Process 206

2.3. Covalently Bonded Particles 207

2.3.1. Foreign Bonded Particles 207

2.3.2. Native Bonded Particles 208

2.3.2.1. Cleaning Solution Containing a Component with a Low Dissociation Constant 211

2.3.2.2. Stream Cleaning Solution 212

2.3.2.3. Spray Cleaning 213

2.4. Zeta Potential 213

2.4.1. Factors Affecting the Zeta Potential 215

2.4.1.1. pH 215

2.4.1.2. Effect of Concentration 215

2.4.2. Measurement of the Zeta Potential 216

3. Cleaning of Organic Contaminants 217

4. Effects of Surfactants in Cleaning Solutions 218

5. Wet Cleaning for Removing Trace Metals after Etching Process 220

5.1. Aluminum 221

5.2. Gold 222

5.3. Chromium 222

5.4. Indium Tin Oxide 222

5.5. Titanium Tungsten 222

5.6. Copper 222

5.7. Nickel 223

5.8. Gallium Arsenide 223

6. Silicon Product Wet Etching Process 223

6.1. Silica Isotropic and Anistropic Etching 224

6.2. Silicon Isotropic and Anisotropic Etching Process 224

6.3. Silicon Nitride 226

6.4. Dry Etching Process 226

6.5. Advantages and Disadvantages of Dry Versus Wet Etching 227

7. Summary and Conclusions 227

References 85

Index 230

UV-Ozone Cleaning for Removal of Surface Contaminants

Rajiv Kohli The Aerospace Corporation, Houston, Texas, USA

Abstract

An overview of the ultraviolet-ozone (UV-O3) method for removal of surface contaminants is provided. UV-O3 is an effective method for removing a variety of contaminants from various surfaces. It is a simple-to-use dry process which is inexpensive to set up and operate. It can produce near-atomically clean surfaces, in air or in a vacuum system, at ambient temperatures. Recent applications of UV-O3 cleaning for removal of surface contaminants are discussed.

Keywords

Ultraviolet (UV)

Ozone

Cleaning

Surface contaminants

Mercury lamp

Xenon excimer lamp

Reference kilogram masses

Chapter Contents

1 Introduction 71

2 Surface Contamination and Cleanliness Levels 72

3 Principles of UV-Ozone Cleaning 73

4 Process Variables 78

4.1 UV Sources 78

4.2 Distance from the Source 78

4.3 Precleaning 78

4.4 Types of Contaminants 79

4.5 Types of Substrates 79

5 Cleaning Systems 79

5.1 Costs 85

5.1.1 Examples of Cost Savings 85

6 Advantages and Disadvantages of UV-Ozone Cleaning 86

6.1 Advantages 86

6.2 Disadvantages 87

7 Applications 88

7.1 Semiconductor and Electronics Parts 89

7.2 Cleaning of Reference Masses 90

7.3 Solar Wind Sample Collectors 90

7.4 Metal Surfaces 90

7.5 Glass and Optical Materials 91

7.6 Probe Tips 92

7.7 Decontamination of Incubator Cabinets 92

7.8 Preparation of Samples for Trace Element Analysis 93

7.9 Polymer Surfaces 93

7.10 Textiles and Fabrics 94

8 Summary 94

Disclaimer 94

References 95

Acknowledgment

The author would like to thank the members of the STI Library at the Johnson Space Center for help with locating obscure reference articles.

1 Introduction

Removal of surface contaminants is essential to all processes where the surface must be modified in some manner, such as deposition of thin films, bonding, or surface patterning. Both organic and inorganic contaminants can cause unreliable bonding or even prevent continuous bonding. Wet and dry cleaning are well-established processes for removal of surface contaminants in a variety of industrial applications. Many of the conventional solvents used for wet cleaning, such as hydrochlorofluorocarbons (HCFCs), are considered detrimental to the environment and are increasingly subject to regulations for reduction in their use and eventual phase out [1–3]. As a result, there is a continuing effort to find alternate cleaning methods to replace solvent cleaning. Several dry cleaning methods have been developed and have been commercialized using lasers, microabrasives, plasma, ultraviolet (UV)-ozone (UV-O3), solid gas pellets or soft snow (CO2, Ar-N2), electrostatic charge, water ice crystals, micro- and nanoparticle beams, and high-velocity air jets [4–6]. UV-O3 is a highly effective method for removal of organic surface contaminants to near-atomic levels. Compared to other dry surface treatment techniques, UV-O3 treatment has the distinctive advantages that it can be conducted under atmospheric pressure, and hence the equipment and running costs are relatively low. Gas plasma (oxygen, hydrogen plasmas), in particular, can have a significant sputtering effect as it contains a complex mixture of protons, electrons, ions, radicals, and excited species with high kinetic energy. In contrast, UV-O3 cleaning is milder than the oxygen plasma due to the absence of high kinetic energy particles. This means that the UV-O3 cleaning method can complement conventional cleaning techniques based on oxygen or hydrogen plasma for a variety of applications. UV-O3 can be used for removal of surface contaminants and for modification of the surface. Several reviews of the technology have been published [7–12]. The intent of this chapter is to provide an overview and discuss recent applications of UV-O3 cleaning for removal of surface contaminants.

2 Surface Contamination and Cleanliness Levels

The most common categories of surface contaminants include particles, thin film or molecular contamination that can be organic or inorganic, ionic contamination, and microbial contamination [13]. Other contaminant categories include metals, toxic and hazardous chemicals, radioactive materials, and biological substances, which are identified for surfaces employed in specific industries. Surface contamination can be in many forms and may be present in a variety of states on the surface. Common contamination sources can include machining oils and greases, hydraulic and cleaning fluids, adhesives, waxes, human contamination, and particulates. In addition, a whole host of other chemical contaminants from a variety of sources may soil a surface. Typical cleaning specifications are based on the amount of specific or characteristic contaminant remaining on the surface after it has been cleaned.

Cleanliness levels in precision technology applications are typically specified for particles by size (in the micrometer (μm) size range) and number of particles, as well as for hydrocarbon contamination represented by nonvolatile residue (NVR) in mass per unit area for surfaces or mass per unit volume for liquids [14–18]. The cleanliness levels are based on contamination levels established in industry standard IEST-STD-CC1246D for particles from Level 1 to Level 1000 and for NVR from Level AA5 (10 ng/0.1 m2) to Level J (25 mg/0.1 m2) [17]. The cleanliness levels have been revised or redesignated in revision E of this standard [18]. The maximum allowable number of particles for each particle size range has been rounded in revision E, while the NVR designation levels have been replaced with a single letter R followed by the maximum allowable mass of NVR. For example, former NVR level J has the new designation R25; level A/2 is now R5E-1; and level AA5 is now R1E-5. These changes are discussed in greater detail in Volume 7 of this series [13].

Many of the products and manufacturing processes are also sensitive to, or they can even be destroyed by, airborne molecular contaminants (AMCs) that are present due to external, process or otherwise generated sources, making it essential to monitor and control AMCs. AMC is chemical contamination in the form of vapors or aerosols that can be organic or inorganic, and it includes everything from acids and bases to organometallic compounds and dopants [19,20]. A new standard ISO 14644–10, “Cleanrooms and associated controlled environments—Part 10: Classification of surface cleanliness by chemical concentration” [21] is now available as an international standard that defines the classification system for cleanliness of surfaces in cleanrooms with respect to the presence of chemical compounds or elements (including molecules, ions, atoms, and particles).

In many commercial applications, the precision cleanliness level is defined as an organic contaminant level of less than 10 μg of contaminant per cm2, although for many applications the requirement is set at 1 μg/cm2 [17,18]. These cleanliness levels are either very desirable or are required by the function of parts such as medical devices, electronic assemblies, optical and laser components, precision mechanical parts, and computer parts.

3 Principles of UV-Ozone Cleaning

The basic principle of UV-O3 cleaning for removal of surface contaminants involves the reduction of organic contaminants into...

| Erscheint lt. Verlag | 3.6.2015 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik ► Bauwesen | |

| Technik ► Elektrotechnik / Energietechnik | |

| Technik ► Maschinenbau | |

| Wirtschaft ► Betriebswirtschaft / Management ► Unternehmensführung / Management | |

| ISBN-10 | 0-323-31271-3 / 0323312713 |

| ISBN-13 | 978-0-323-31271-4 / 9780323312714 |

| Haben Sie eine Frage zum Produkt? |

Größe: 16,9 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: PDF (Portable Document Format)

Mit einem festen Seitenlayout eignet sich die PDF besonders für Fachbücher mit Spalten, Tabellen und Abbildungen. Eine PDF kann auf fast allen Geräten angezeigt werden, ist aber für kleine Displays (Smartphone, eReader) nur eingeschränkt geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

Größe: 13,2 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich