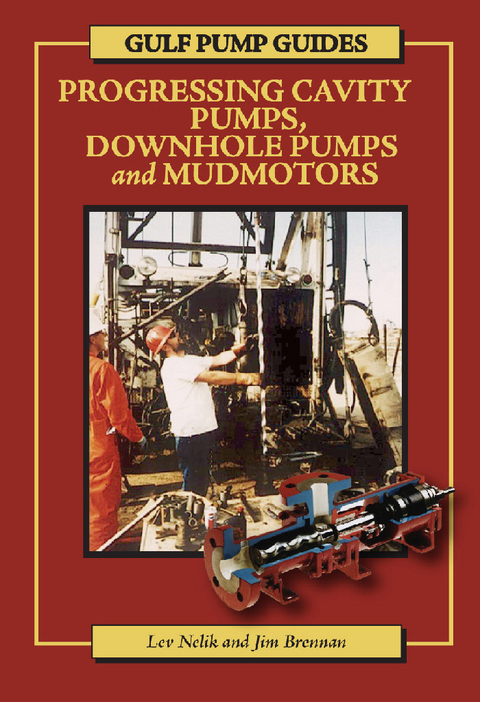

Gulf Pump Guides: Progressing Cavity Pumps, Downhole Pumps and Mudmotors (eBook)

214 Seiten

Elsevier Science (Verlag)

978-0-12-799971-5 (ISBN)

Written by one of the world's foremost authorities on pumps, this first volume in Gulf Publishing Company's Gulf Pump Guides series covers the design, application and troubleshooting for progressing cavity pumps, downhole pumps and mudmotors. There is no other volume offering a more comprehensive, easy-to-understand and hands-on coverage of these types of pumps. As they become more and more widely used in the petrochemical industry and other industries, knowledge of their design and application will become increasingly more important for the engineer.

GEOMETRY

At first glance, the geometry of a PC pump hydraulic section (we will also apply this concept to DHPs and DHMs) could be discouragingly complex, which is probably why it is relatively poorly understood, even among users and within the engineering community. Not much information has been published that would explain the intricacies of the PC geometry in a clear, straightforward, and simple fashion. Consider, again, the assembled rotor/stator pair, as was shown in Fig. 5. Depending on the lobe ratio, the cross sections would look as shown in Fig. 6.

FIGURE 6 Cross-sectional view (perpendicular to pump axis) of various lobe ratios.

Because the number of rotor and stator lobes differ by one, a fluid-filled cavity is formed between a rotor and a stator. This is a key to its operating principle.

Cavity/Displacement

Consider the shape of the cavity for the simplest case, a single-lobe rotor (1:2 lobe ratio, i.e., two stator lobes). Several cavities can actually be seen in Fig. 5, as if frozen in time during the rotor rotation. For simplicity, a single stage is shown, but pumps usually have several stages, depending on the overall pressure differential between the suction and discharge. In Fig. 5, Sections 8′ and 2′ could be thought of as belonging to the adjacent stages, if there were any. The first (entrance) section shows the rotor positioned at the top extremity of the stator profile. As we move along the z-axis, the stator sections “turn” circumferentially until a complete 360-degree turnaround is reached at the other end, at the axial distance equal to stator pitch (Ps). To create an enclosed cavity, the rotor section must also “twist” around along the z-axis, but twice. The rotor completes its first 360-degree turnaround at the middle of the stator, and the second 360 degrees during the second half of the stator pitch (i.e., the rotor pitch (Pr) is equal to one-half of the stator pitch (Ps), for the case of a 1:2 lobe configuration). For multilobe cases, the ratio of pitches is equal to the lobe ratio (i.e., Ps/Pr = Ns/Nr).

Because of the rotor eccentricity (to be discussed below), the rotation of the rotor is similar to a car wheel when being driven along a road—the motion is actually an instantaneous rotation around the point of contact between the wheel and the road (and not around the center of the wheel). There is rolling with no sliding, as shown in Fig. 7. Point A generates a trajectory, called a cycloid.

FIGURE 7 Rolling of a car wheel. Point B shows instantaneous rotation around point A. Distance AA’ is equal to the wheel’s circumference.

If we examine positions of the stator sections in Fig. 5 at time t = 0, we can see several cavities. One of the cavities is starting from zero, opening at the top of the entry section (Section 1), and gradually opening as the section twists around—the small top cavity area at Section 2 (the 45-degree position). It grows slightly larger at Section 3, reaches the maximum at Section 5 (180 degrees, bottom of the stator), and then twists over on the other side. At the same time it is beginning to diminish, and eventually comes back to zero (the opening at Section 9), which is the end of the stator pitch (i.e., the end of one stage).

This cavity [“top,” Fig. 5(c)] is at maximum volume; it has zero opening at the inlet and exit sections and maximum opening in the middle of the stator pitch. At the same time, another cavity [Fig. 5(b)] occupies one-half of the stator pitch length, and has maximum opening at the inlet cross section, gradually diminishing toward the middle. From the middle, yet another cavity begins again and reaches maximum opening at the exit. Therefore, as the first cavity grows as we move along the axis, the second one becomes smaller and reaches zero volume just when the first one reaches its maximum, at Section 5. A third cavity starts off just where the second expires, and grows in a fashion similar to the first cavity, except that it starts at Section 5 (instead of Section 1, where the first cavity begins its growth). By the time the sections reach the end of the stator stage length (Section 9), the third cavity reaches its maximum size at the discharge cross section.

The above describes the position of a rotor within the stator at a given time (i.e., with shaft revolution “frozen”). If we now examine the position of the rotor at the next time frame during the rotation (e.g., ⅛ of a shaft turn, or 45 degrees), each rotor cross section (which are circles for the single-lobe case) will rotate similar to car wheels, as described in Fig. 7. The rotor in Section 2 [Fig. 5(d)] will move out a little, allowing the fluid to fill it, and so would Sections 3 and 4. Section 5 moves in, away from the stator extremity, pushing the liquid axially toward the next section. Sections 6, 7, and 8 will all perform similar movements, each receiving the same portion of fluid from the earlier sections, and at the same time displacing their own fluid toward the discharge. The cavity in Section 9 opens up to receive fluid from Section 8, while displacing its own fluid into the discharge. As shaft rotation continues, when the rotor reaches the lower stator extremity at Section 1, the cavity will travel one-half of its cycle (one-half shaft turn), and the first cavity will now be starting at the bottom in Section 1, reaching its maximum at the top of Cross Section 5, and diminishing back to zero at Section 9.

This process is continuous, resulting in smooth and continuous displacement of fluid from suction to discharge, similar to an auger inside a pipe. The movement of fluid is close to axial, but not exactly. In an auger, flow direction is straight due to the straight pipe ID, but the stator lobes deviate (guide the fluid) from the axially straight path, and its shape resembles a helix, which leads to helical motion of the pumped fluid. However, the rotational component of the fluid is small, which results in a low shear rate; this is why PC pumps are often used to transport fruits, vegetables, and other delicate products suspended in water with little damage.

If we “unwrap” the cavity from three dimensions and try to construct an equivalent two-dimensional representation, it will look as shown in Fig. 8, illustrating how pressure changes inside the cavity during the rotation cycle.

FIGURE 8 An “unwrapped” cavity. At top, cavity (1) is halfway with completing its travel through the stator and is at discharge pressure pd. Cavity (2) is at its extreme position (same as “top” cavity shown in Fig. 5) and contains liquid still at suction pressure, just about ready to open up to discharge pressure. Cavity (3) is halfway inside the stator and is also at suction pressure. At bottom, shaft turned ¼ turn. Cavity (1) mostly completed its travel through the stator; cavity (2) opened up to discharge pressure (theoretically instantaneous pressure change); cavity (3) keeps growing into the stator; cavity (4) is just beginning to enter the stator.

PC pumps are known to have low pulsations due to relatively straight flow path and low turbulence. However, there exists a small cyclical variation in pressure, as can be seen from Fig. 9, which reflects the progression of cavities inside the pump in accordance with rotor rotation.

FIGURE 9 Pressure pulsations at a given point inside the pump, with the same magnitude but higher frequency as the lobe ratio is increased.

Theoretically, fluid pressure changes instantaneously from suction to discharge. The result is a steplike change pressure fluctuation, alternating from suction to discharge values with a frequency of 1 × rpm for a 1:2 lobe case, or Nr × rpm for multilobes, in accordance with the concept of rotor nutations around a stator center. A concept of rotor nutations around a stator center is shown in Fig. 10.

FIGURE 10 Concept of rotor nutation for a 3:4 lobe ratio. During one rotation of the input shaft, the rotor “nutated” three times. Note that the direction of the nutation is opposite to the input shaft rotation. The insert shows a simplified case for a wheel (circle).

Some pressure smoothing results due to interleakage as well as viscous friction. For multistage units, pressure fluctuations are based on per-stage values (i.e., the net pressure drop between suction and discharge divided by the number of stages). This reduces pressure pulsations even further. There is an interesting analogy between multilobe progressing cavity pumps (or mudmotors) and centrifugal pumps: for multilobe pumps, a mechanism of pressure pulsations is similar to “vane pass” frequencies characteristic of centrifugal pumps, caused by the impeller tips passing by the volute tongue or diffusor vane inlets.

Since pump unit displacement (qo, flow per shaft revolution at zero load, indicated by the zero subscript) involves cavity volume (or several cavities for multilobe rotors), it is important to be able to calculate this volume. Even though the shape of the cavity is complex, there is a simple way to calculate its volume. The net fluid cross-sectional area (Fig. 5) is constant along the...

| Erscheint lt. Verlag | 25.11.2013 |

|---|---|

| Sprache | englisch |

| Themenwelt | Technik ► Bauwesen |

| Technik ► Elektrotechnik / Energietechnik | |

| Technik ► Maschinenbau | |

| Wirtschaft | |

| ISBN-10 | 0-12-799971-X / 012799971X |

| ISBN-13 | 978-0-12-799971-5 / 9780127999715 |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich