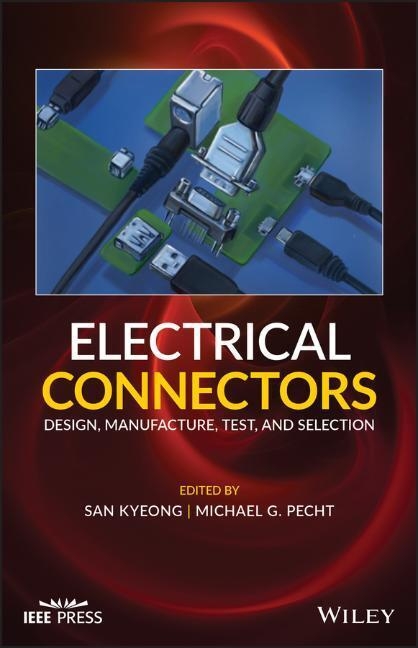

Electrical Connectors

Wiley-IEEE Press (Verlag)

978-1-119-67976-9 (ISBN)

Electrical Connectors: Design, Manufacture, Test, and Selection delivers a comprehensive discussion of electrical connectors, from the components and materials that comprise them to their classifications and underwater, power, and high-speed signal applications. Accomplished engineer and author Michael G. Pecht offers readers a thorough explanation of the key performance and reliability concerns and trade-offs involved in electrical connector selection.

Readers, both at introductory and advanced levels, will discover the latest industry standards for performance, reliability, and safety assurance. The book discusses everything a student or practicing engineer might require to design, manufacture, or select a connector for any targeted application. The science of contact physics, contact finishes, housing materials, and the full connector assembly process are all discussed at length, as are test methods, performance, and guidelines for various applications.

»Electrical Connectors« covers a wide variety of other relevant and current topics, like:

- A comprehensive description of all electrical connectors, including their materials, components, applications, and classifications

- A discussion of the design and manufacture of all parts of a connector

- Application-specific criteria for contact resistance, signal quality, and temperature rise

- An examination of key suppliers, materials used, and the different types of data provided

- A presentation of guidelines for end-users involved in connector selection and design

Perfect for connector manufacturers who select, design, and assemble connectors for their products or the end users who concern themselves with operational reliability of the system in which they're installed, Electrical Connectors also belongs on the bookshelves of students learning the basics of electrical contacts and those who seek a general reference with best-practice advice on how to choose and test connectors for targeted applications.

San Kyeong is a staff engineer at the R&D headquarters of Samsung Electro-Mechanics Company, currently working as a Research Scientist with the Center for Advanced Life Cycle Engineering (CALCE), University of Maryland, USA. He received a BE degree and PhD in chemical and biological engineering from the Seoul National University of Seoul, South Korea, in 2010 and 2016, respectively. He has expertise in material engineering for passive electronic components.

Michael G. Pecht, PHD, is Chair Professor and Director of the Center for Advanced Life Cycle Engineering (CALCE) at the University of Maryland, USA. He received his PhD in Engineering Mechanics from the University of Wisconsin at Madison, USA. He is an IEEE, ASME, SAE, and IMAPS Fellow.

About the Editor

List of Contributors

preface

1. CONNECTORS

1.1. Challenges of Separable Connectors

1.2. Components of a Connector

1.2.1. Contact Springs

1.2.2. Contact Finishes

1.2.2.1. Noble Metal Contact Finishes

1.2.2.2. Non-noble Metal Contact Finishes

1.2.3. Connector Housing

1.2.4. Contact Interface

1.3. Connector Types

1.3.1. Board-to-Board Connectors

1.3.2. Wire/Cable-to-Wire/Cable Connectors

1.3.3. Wire/Cable-to-Board Connectors

1.4. Connector Terminology

2. CONNECTOR HOUSING

2.1. Mechanical Properties

2.2. Electrical Properties

2.3. Flammability

2.4. Temperature Rating

2.5. Housing Materials

2.5.1. Thermoplastic Polymers

2.5.1.1. Polyesters

2.5.1.2. Polyimides, Polyamide-imides, and Polyetherimides

2.5.1.3. Polyphenylene Sulfides

2.5.1.4. Polyether Ether Ketones

2.5.1.5. Liquid-crystalline Polymers

2.5.1.6. Comparison of Thermoplastic Polymers

2.5.2. Thermosetting Polymers

2.5.3. Additives to Housing Materials

2.5.4. Manufacturing of Housing Materials

3. CONTACT SPRING

3.1. Copper Alloys

3.1.1. Unified Number System (UNS)

3.1.2. Properties of Copper Alloys

3.2. Nickel Alloys

3.3. Conductive Elastomers

3.4. Contact Manufacturing

4. CONTACT PLATING

4.1. Noble Metal Plating

4.1.1. Gold

4.1.2. Palladium

4.1.3. Combination of Gold and Palladium

4.2. Non-noble Metal Plating

4.2.1. Silver

4.2.1.1. Characteristics of Silver as a Contact Finish

4.2.1.2. Potential Tarnish-Accelerating Factors

4.2.1.3. Use of Silver in Typical Connectors

4.2.1.4. Managing Silver Corrosion

4.2.2. Silver-Palladium Alloys

4.2.3. Nanocrystalline Silver Alloys

4.2.4. Silver-Bismuth Alloys

4.2.5. Tin

4.2.6. Nickel Contact Finishes

4.3. Underplating

4.4. Plating Process

4.4.1. Electrolytic Plating

4.4.2. Electroless Plating

4.4.3. Cladding

4.4.4. Hot Dipping

5. CONNECTOR INSERTION AND EXTRACTION

5.1. Insertion and Extraction Forces

5.2. Contact Retention

5.3. Contact Force and Deflection

5.4. Contact Wipe

6. CONTACT INTERFACE

6.1. Constriction Resistance

6.2. Contact Resistance

6.3. Other Factors Affecting Contact Resistance

6.4. Current Rating

6.5. Capacitance and Inductance

6.6. Bandpass and Bandwidth

7. THE BACK-END CONNECTION

7.1. Connection Through Soldering

7.2. Press-fit Connection

7.3. Crimping Connection

7.4. Insulation Displacement Connection

8. LOADS AND FAILURE MECHANISMS

8.1. Environmental Loads

8.1.1. Temperature

8.1.2. Vibration Load

8.1.3. Humidity

8.1.4. Contamination

8.1.5. Differential Pressure

8.2. Failure Mechanisms in Electrical Connectors

8.2.1. Silver Migration

8.2.2. Tin Whiskers

8.2.3. Corrosion Failure

8.2.4. Arc Formation

8.2.5. Creep Failure

8.2.6. Wear

8.2.7. Frictional Polymerization

8.3. Case Study by NASA: Electrical Connectors for Spacecraft

9. FRETTING IN CONNECTORS

9.1. Mechanisms of Fretting Failure

9.1.1. Material Factors That Affect Fretting

9.1.1.1. Contact Materials

9.1.1.2. Hardness

9.1.1.3. Surface Finish

9.1.1.4. Frictional Polymerization

9.1.1.5. Grain Size

9.1.1.6. Oxides

9.1.1.7. Coefficient of Friction

9.1.1.8. Electrochemical Factor

9.1.2. Operating Factors That Affect Fretting

9.1.2.1. Contact Load

9.1.2.2. Fretting Frequency

9.1.2.3. Slip Amplitude

9.1.2.4. Electric Current

9.1.3. Environmental Factors That Affect Fretting

9.1.3.1. Humidity

9.1.3.2. Temperature

9.1.3.3. Dust

9.2. Reducing the Damage of Fretting

9.2.1. Lubrication

9.2.2. Improvement in Design

9.2.3. Coatings

10. TESTING

10.1. Dielectric Withstanding Voltage Testing

10.2. Insulation Resistance Testing

10.3. Contact Resistance Testing

10.4. Current Rating

10.5. Electromagnetic Interference and Electromagnetic Compatibility Testing

10.6. Temperature Life Testing

10.7. Thermal Cycling Testing

10.8. Thermal Shock Testing

10.9. Steady-State Humidity Testing

10.10. Temperature Cycling with Humidity Testing

10.11. Corrosion

10.11.1. Dry Corrosion

10.11.2. Creep Corrosion

10.11.3. Moist Corrosion

10.11.4. Fretting Corrosion

10.12. Mixed Flowing Gas Testing

10.12.1. Battelle Labs MFG Test Methods

10.12.2. EIA MFG Test Methods: EIA 364-TP65A

10.12.3. IEC MFG Test Methods: IEC 68-2-60 Part 2

10.12.4. Telcordia MFG Test Methods: Telcordia GR-63-CORE Section 5.5

10.12.5. IBM MFG Test Methods: G1(T)

10.12.6. CALCE MFG Chamber Capability

10.13. Vibration

10.13.1. Mechanical Shock

10.13.2. Mating Durability

10.14. Highly Accelerated Life Testing

10.15. Environmental Stress Screening

11. SUPPLIER SELECTION: RELIABILITY CAPABILITY ASSESSMENT

11.1. Connector Reliability

11.2. Capability Maturity Models

11.3. Key Reliability Practices

11.3.1. Reliability Requirements and Planning

11.3.2. Training and Development

11.3.3. Reliability Analysis

11.3.4. Reliability Testing

11.3.5. Supply-Chain Management

11.3.6. Failure Data Tracking and Analysis

11.3.7. Verification and Validation

11.3.8. Reliability Improvement

11.4. Reliability Capability of an Organization

11.5. The Evaluation Process

12. SELECTING THE RIGHT CONNECTOR

12.1. Connector Requirements Based on Design and Targeted Application

12.2. Mating Cycles

12.3. Current and Power Ratings

12.4. Environmental Conditions

12.5. Termination Types

12.6. Materials

12.6.1. Connector Housing Materials

12.6.2. Connector Spring Materials

12.7. Contact Finishes

12.8. Reliability

12.9. Raw Cables and Assemblies

12.10. Supplier Reliability Capability Maturity

12.11. Connector Selection Team

12.12. Selection of Candidate Parts from a Preferred Parts Database

12.13. Electronic Product Manufacturers' Parts Databases

12.14. Parts Procurement

12.15. Parts Availability

12.16. High-Speed Connector Selection

12.17. NASA Connector Selection

12.18. Harsh Environment Connector Selection

12.19. Fiber Optic Interconnect Requirements by Market

12.20. High-Power Subsea Connector Selection

12.20.1. Undersea Connector Reliability

12.21. Screening Tests

12.22. Low-Voltage Automotive Single- and Multiple-Pole Connector Validation

12.23. Failure Modes, Mechanisms, and Effects Analysis for Connectors

12.24. Connector Experiments

12.25. Summary

13. SIGNAL CONNECTOR SELECTION

13.1. Issues Involving High-Speed Connectors

13.2. Signal Transmission Quality Considerations

13.2.1. Interconnect Delays

13.2.2. Signal Distortion

13.3. Electromagnetic Compatibility

13.4. Virtual Prototyping

13.4.1. TDR Impedance Measurements

13.4.1.1. Reflection Coefficient

13.4.1.2. TDR Resolution Factors

13.4.1.3. TDR Accuracy Factors

13.5. Vector Network Analyzer

13.6. Simulation Program with Integrated Circuit Emphasis (SPICE)

14. ADVANCED TECHNOLOGY ATTACHMENT CONNECTORS

14.1. ATA Connector and SATA Connector Overview

14.2. History of ATA and SATA

14.3. Physical Description of ATA Connectors, ATA Alternative Connectors, and SATA Connectors

14.4. ATA Standardization and Revisions

14.5. SATA Standardization and Revisions

14.6. SATA in the Future

15. POWER CONNECTORS

15.1. Requirements for Power Connectors

15.2. Power Connector Materials

15.3. Types of Power Connectors

15.4. Power Contact Resistance

15.5. Continuous, Transient, and Overload Current Capacities

15.5.1. Continuous Current Capacity

15.5.2. Transient Current Capacity

15.5.3. Overload Current Capacity

15.6. Current Rating Method

16. ELECTRICAL CONNECTORS FOR UNDERWATER APPLICATIONS

16.1. Background and Terminology

16.1.1. History

16.1.2. Terminology

16.2. Commercial Off-the-Shelf (COTS) Connectors

16.2.1. Rubber-molded

16.2.2. Rigid-shell or Bulkhead Assemblies

16.2.3. Fluid-filled Underwater Mateable

16.2.4. Inductive Coupling

16.2.5. Assemblies (Non-mateable)

16.3. Connector Design

16.3.1. Thermal Design

16.3.2. Electrical Properties

16.3.3. Mechanical Properties

16.3.4. Material Choices

16.3.5. Specifications for Underwater Connectors

16.4. Connector Deployment and Operation

16.4.1. Connection Procedure

16.4.2. Connection Layout

16.4.3. Reliability

16.5. Discussion and Conclusion

17. EXAMPLES OF CONNECTORS

17.1. Amphenol ICC M-Series (TM) 56 Connectors

17.2. Amphenol ICC Paladin (R) Connectors

17.3. Amphenol ICC 3000W EnergyEdge (TM) X-treme Card Edge Series

17.4. Amphenol ICC FLTStack Connectors

17.5. Amphenol ICC HSBridge Connector System

17.6. Amphenol ICC MUSBR Series USB 3.0 Type-A Connectors

17.7. Amphenol ICC Waterproof USB Type-C (TM) Connectors

17.8. Amphenol ICC NetBridge (TM) Connectors

17.9. Amphenol Sine DuraMate (TM) AHDP Circular Connectors

17.10. Amphenol Aerospace MIL-DTL-38999 Series III Connectors

17.11. Fischer Connectors UltiMate (TM) Series Connectors

17.12. Hirose Electric DF50 Series Connectors

17.13. Hirose Electric microSD (TM) Card Connectors

17.14. Molex SAS-3 and U.2 (SFF-8639) Backplane Connectors

17.15. Molex NeoPress (TM) Mezzanine Connectors

17.16. Molex Impel (TM) Plus Backplane Connectors

17.17. Molex EXTreme Guardian (TM) Power Connectors

17.18. Molex Imperium (TM) High Voltage/High Current Connectors

17.19. TE Connectivity Free Height Connectors

17.20. TE Connectivity STRADA Whisper Connectors

17.21. TE Connectivity MULTI-BEAM High-Density (HD) Connectors

17.22. TE Connectivity HDMI (TM) Connectors

17.23. TE Connectivity AMP CT Connector Series

17.24. TE Connectivity Micro Motor Connectors

17.25. TE Connectivity AMPSEAL Connectors

17.26. TE Connectivity M12 X-code Connectors

17.27. TE Connectivity SOLARLOK 2.0 Connectors

17.28. TE Connectivity Busbar Connectors

APPENDIX: STANDARDS

A.1. Standard References for Quality Management and Assurance

A.2. General Specifications for Connectors

A.3. Safety-Related Standards and Specifications

A.4. Standard References for Connector Manufacturing

A.5. Standard References for Socket Material Property Characterization

A.6. Standard References for Socket Performance Qualification

A.7. Standard References for Socket Reliability Qualification

A.8. Other Standards and Specifications

A.9. Telcordia

A.10. Society of Cable Telecommunications Engineers (SCTE)

A.11. Electronic Industries Alliance/Telecommunications Industry Association (EIA/TIA)

A.12. International Electrotechnical Commission (IEC)

A.12.1 IEC Standards

A.12.2 IEC Connectors

A.13. Military Standards (MIL-STD)

A.14. Standards for Space-Grade Connectors

| Erscheinungsdatum | 02.02.2021 |

|---|---|

| Reihe/Serie | Wiley - IEEE |

| Verlagsort | Hoboken |

| Sprache | englisch |

| Maße | 170 x 244 mm |

| Gewicht | 856 g |

| Einbandart | gebunden |

| Themenwelt | Technik ► Elektrotechnik / Energietechnik |

| Technik ► Nachrichtentechnik | |

| ISBN-10 | 1-119-67976-1 / 1119679761 |

| ISBN-13 | 978-1-119-67976-9 / 9781119679769 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich