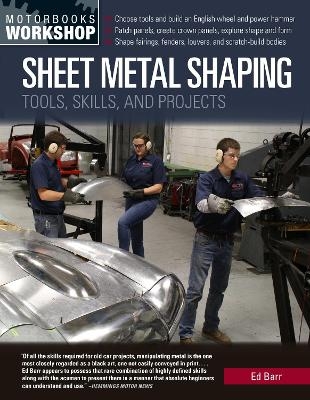

Sheet Metal Shaping

Motorbooks (Verlag)

978-0-7603-6574-8 (ISBN)

Sheet Metal Shaping demystifies this seemingly black art with information on tools and basic skills and 14 customizable projects, fully illustrated with step-by-step color photography.

Whether you want to create custom or replacement parts or build an entire automobile body, this metalworking course for gearheads from award-winning automotive-restoration author and professor Ed Barr will take you as far as your interests reach.

First, you’ll learn how to assemble your ideal toolkit, as well as how to build a power hammer and an English wheel. In the process, Barr will help you make informed choices based on available space and budget. Once you’re all set up, he addresses the concepts of shape and form.

The projects are presented in a way that you can easily apply them to your own vehicles, whatever they may be. Barr also takes the time to show how the projects can be accomplished with different available tools.

As you go, you’ll gain the skills and confidence for tackling the increasingly complex cases presented. Work your way up to building a fender utilizing the wheeling machine you built earlier; then move on to building a Model T speedster body and an Indy car, and later a challenging ’34 Plymouth fender. The book even includes common goofs and how to avoid and, if necessary, correct them.

Written in an engaging and approachable style, Sheet Metal Shaping serves equally well as a useful supplement to Barr’s previous Professional Sheet Metal Fabrication or as a must-have standalone volume for any fabricator’s library.

The Motorbooks Workshop series covers the topics that engage and interest gearheads. Written by authorities in the subject matter and illustrated with color photography, Motorbooks Workshop is the ultimate source for how-to know-how.

Ed Barr, best-selling author of Professional Sheet Metal Fabrication, teaches welding and sheet metal restoration in the Technology Department at McPherson College in McPherson, Kansas. Barr has been restoring cars and creating metal sculpture since he was a teenager. Barr graduated from the University of the South in 1991 and pursued a career in art museum administration after receiving an MA degree from the University of Kansas. Barr then served as director of the Mulvane Art Museum at Washburn University in Topeka, Kansas. Barr earned a BS degree in automotive restoration technology from McPherson College and subsequently worked at Vintage Restorations Ltd. in Union Bridge, Maryland, where he restored British cars. He resides in McPherson, Kansas. www.mcpherson.edu/academics/autorestoration

Introduction 4

Chapter 1 The Peasant’s Toolkit 6

Chapter 2 Building Your Own English Wheel 14

Chapter 3 Building a Power Hammer from a Kit 26

Chapter 4 Introduction to Shape and Form 40

Chapter 5 The Low Crown Panel 46

Chapter 6 The High Crown Panel 54

Chapter 7 The Reverse Curve Panel 62

Chapter 8 Scratch-Built Fender 70

Chapter 9 Patch Panelpalooza 74

Chapter 10 Shiny Trim Repair 96

Chapter 11 The Nayslayer Model T Speedster 104

Chapter 12 Re-creating an Indy Race Car 122

Chapter 13 Building an Aluminum Motorcycle Fairing 140

Chapter 14 Building a Pair of Early Cadillac Fenders 148

Chapter 15 Building a ’34 Plymouth Fender 166

Chapter 16 Pourable Foam Buck 192

Chapter 17 Louvered Hoods 202

Chapter 18 MGB “Zagato” 220

Resources 236

Index 237

About the Author 240

| Erscheinungsdatum | 27.04.2019 |

|---|---|

| Reihe/Serie | Motorbooks Workshop |

| Zusatzinfo | 400 color & b-w photos |

| Sprache | englisch |

| Maße | 210 x 270 mm |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten |

| Technik ► Fahrzeugbau / Schiffbau | |

| ISBN-10 | 0-7603-6574-1 / 0760365741 |

| ISBN-13 | 978-0-7603-6574-8 / 9780760365748 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich