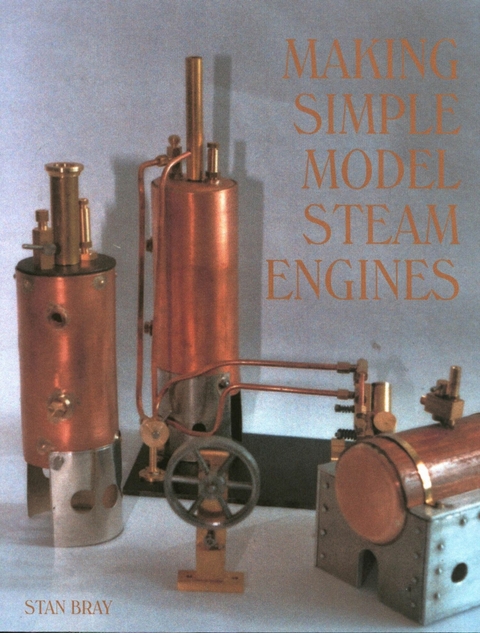

Making Simple Model Steam Engines (eBook)

160 Seiten

The Crowood Press (Verlag)

978-0-7198-4357-0 (ISBN)

Stan Bray is a model engineer of long experience. He is founder of Model Engineer's Workshop, former editor of Engineering in Miniature and associate editor of Model Engineer. He has written many books including Metalworking - Tools and Techniques for Crowood.

PART ONE

INTRODUCTION

Getting Started

Steam engines led the industrial revolution; their introduction into industry changed the way goods are produced, and therefore subsequently the way in which human beings live. Some will say this is a pity, as life now has a far quicker pace than it did before the industrial revolution, but others feel that the advantages of mechanization far outweigh the many disadvantages that it brought with it. Of course generally the steam engine as a means of power has long been superseded by the use of oilbased fuels and even nuclear power. Even so, much of industry is still powered by steam except that these days it tends to be used in turbines rather than the old-fashioned reciprocating engine.

Basically machines operated by steam are simple: it is a case of boiling water, collecting the steam that is generated in the process, and putting it in a closed cylinder so that it will operate a piston. The trick in being successful is the manner in which the steam is allowed in and out of the cylinder, and there are many methods of doing this, some of which are extremely simple, others that can be quite complicated, the latter engines being developed in the endless search for greater efficiency by the engine designers. This book will only deal with comparatively simple mechanisms; nevertheless, anyone making one of them will build a working engine.

So how does a steam engine work? In this modern world we have electrically operated kettles that switch themselves off as soon as the water boils, but not so very long ago the kettle was boiled on a stove, and when it boiled it was taken off to make the tea, or for whatever purpose. If you forgot the kettle had been put on and left the room, you would come back and find the room absolutely full of vapour, usually referred to as steam, although in fact it is actually the steam condensing. No matter; what it actually is is the result of steam having been generated, but the remarkable thing is that it has completely filled the whole room from a quantity of about a half litre of water. Thus there has obviously been a vast temporary expansion in the quantity, although when it condenses it will return to more or less the original amount.

If instead of leaving the room, the person who put the kettle on remains and perhaps dozes off, they would have been awakened by the sound of the lid of the kettle bouncing up and down. What is happening is that some of the steam cannot escape quickly enough and is pushing the lid off as it expands; obviously then the expansion of the steam is generating some force. It is generally believed that it was this that caused James Watt to develop his interest in steam power, although in fact this is unlikely. Steam had already been in use for many years, and his contribution was to develop and improve the engines that were already in use or being built.

The first steam engines that were put to practical use were built by Thomas Newcomen, and were designed purely as pumps for use in the mines in Cornwall. At that time the full potential of steam had not been realized, and the engines worked on the principle of applying steam to move the piston and then applying cold water to create a vacuum and thus to draw it back from whence it came. The engines were purely reciprocating the connecting rod moving in and out in a straight line.

The fact that the cylinder was cooled each time meant that the engines were very wasteful of steam, and a considerable improvement came about when instead of cooling the cylinder, the used steam was allowed to exhaust. This meant that two taps – or ‘cocks’ as they are always referred to in steam parlance – were required, one to allow steam in, the other to allow the exhaust out. These were operated manually, a task usually given to boys, which must have been boring in the extreme, particularly as the working day would have been twelve or even fourteen hours. It is not recorded how many times the lad doing this operation might have fallen asleep or lost concentration, and in doing so would have brought the whole of the pumping operation to a standstill; the mine owner would have been less than pleased.

We can only speculate how long it took, or who it was that first decided that if they connected the two taps to the piston rod of the engine with rope or wire, the taps would open and close by themselves. No doubt in doing so the person responsible gave themselves a nice easy time until what they had done was discovered, when they would probably have been sent elsewhere to work. Whoever it was, they unknowingly invented the first-ever valve gear, and should be hailed as a genius instead of being forgotten, as well as having possibly received punishment.

Even though a primitive valve gear had been discovered, the engines still only worked in a reciprocating movement, and they were still inefficient, and it wasn’t until the crank was invented – something attributed to James Watt – that it became possible to put the steam engine to other uses. The crank enabled the reciprocating motion to be converted to a rotary one, and by adding a heavy flywheel it was then possible for an engine to run continually; moreover the rotary motion could also be used to drive pulleys that operated machinery via belts. From being just a machine for pumping, the steam engine was now a means of powering all sorts of machinery, and it did not take industrialists long to realize the fact.

A feature of the old mills and engineering works was the numerous overhead shafts driven from an engine, each carrying a number of pulleys that in turn were connected to a machine of one sort or another. It was all very noisy, and if the engine stopped for any reason the whole of the mill or factory would grind to a halt; nevertheless it was the beginning of high volume production and the industrial revolution.

Having obtained rotary motion, it was a comparatively short step for it to be adapted to driving a vehicle, and almost immediately attempts were made to fit steam engines to road vehicles, to railway engines and to boats, all of which is well documented. Although very powerful, the steam engine has many disadvantages, and so it was inevitable that other forms of prime mover should eventually displace it for most industrial purposes.

The reciprocating engine has all but disappeared, and where steam is in use, these have been replaced by turbines that are steam driven but work on an entirely different principle. The turbine finds many uses, not least the generation of electricity, and that electricity is usually now used to provide power to operate the more modern versions of the pumps and other machines that were driven by the reciprocating steam engine.

Children like to play with toys, particularly those that represent modern artefacts. Come to that, a considerable number of adults also like to have such toys – except in their case they are referred to as ‘models’. With the industrial revolution in full swing, it was logical that some enterprising manufacturer would quickly make a steam-driven toy for the benefit of children, and in fact it was not just one manufacturer, but a considerable number that produced a range of them. From the early to the mid-nineteen hundreds they were what we now refer to as ‘best sellers’. Most were stationary engines of the simplest form, but there were models as well as toys, and some of the engines were used to drive a range of other models, possibly the most popular of these being steam locomotives, which in those days were the main form of power for public transport. A number of these models were produced to a high standard and it was also possible to buy parts with which to assemble one’s own model, although complete kits of parts were very rare indeed.

As the years went by, other forms of power became common, and with the development of small electric motors the interest in steam engines declined. In all probability this was because turning on a switch was far easier than the effort involved to run the steam engine. In addition, the materials from which toys were made was rapidly changing, so whilst at the turn of the century all mechanical toys were made from sheet metal folded to shape and painted accordingly, the advent of die-casting with low melting-point alloys changed all that, and not only enabled the toys to be produced much more cheaply but also to be more realistic looking. Many of the manufacturers of steam toys and models went out of business or converted to the new methods, with just a handful remaining to make steam-driven toys or models; at least two of these are still enjoying success with them, so the interest has never completely disappeared.

With the exception of a few more sophisticated models, the steam engines were usually of the type known as oscillating engines, and it is this type of engine with which this book mainly deals. The oscillator in full size was used in industry and in particular for marine work, and yet the principle is so simple that a model is very easy to make, and when well made can produce a considerable amount of power; it is even possible to make one with hand tools, such as a file or two and a hand drill. There are examples of such models in this book, although it is mainly about simple models that can be made with the use of a lathe. All the designs can be built using one of the very small machines, such as a Unimat or similar design.

The models vary in complexity, starting with something very simple and developing into more complicated designs. One does not need to be a highly skilled engineer to build them, and in doing so the knowledge of metalworking practices will be gradually improved. The...

| Erscheint lt. Verlag | 21.12.2005 |

|---|---|

| Zusatzinfo | 192 black & white photographs |

| Verlagsort | London |

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Freizeit / Hobby ► Modellbau |

| Schlagworte | Boiler • double-acting • Engine • Imperial • Locomotive • metric • Oscillator • twin-cylinder |

| ISBN-10 | 0-7198-4357-X / 071984357X |

| ISBN-13 | 978-0-7198-4357-0 / 9780719843570 |

| Haben Sie eine Frage zum Produkt? |

Größe: 26,0 MB

DRM: Digitales Wasserzeichen

Dieses eBook enthält ein digitales Wasserzeichen und ist damit für Sie personalisiert. Bei einer missbräuchlichen Weitergabe des eBooks an Dritte ist eine Rückverfolgung an die Quelle möglich.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich