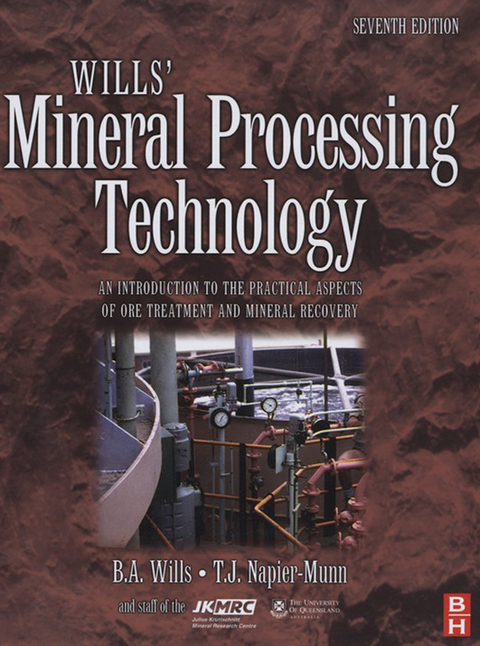

Wills' Mineral Processing Technology (eBook)

456 Seiten

Elsevier Science (Verlag)

978-0-08-047947-7 (ISBN)

Now in its Seventh Edition, this renowned book is a standard reference for the mineral processing industry. Chapters deal with each of the major processing techniques, and coverage includes the latest technical developments in the processing of increasingly complex refractory ores, new equipment and process routes. This new edition has been prepared by the prestigious J K Minerals Research Centre of Australia, which contributes its world-class expertise and ensures that this will continue to be the book of choice for professionals and students in this field.

This latest edition highlights the developments and the challenges facing the mineral processor, particularly with regard to the environmental problems posed in improving the efficiency of the existing processes and also in dealing with the waste created. The work is fully indexed and referenced.

·The classic mineral processing text, revised and updated by a prestigious new team

·Provides a clear exposition of the principles and practice of mineral processing, with examples taken from practice

·Covers the latest technological developments and highlights the challenges facing the mineral processor

·New sections on environmental problems, improving the efficiency of existing processes and dealing with waste.

Wills' Mineral Processing Technology provides practising engineers and students of mineral processing, metallurgy and mining with a review of all of the common ore-processing techniques utilized in modern processing installations. Now in its Seventh Edition, this renowned book is a standard reference for the mineral processing industry. Chapters deal with each of the major processing techniques, and coverage includes the latest technical developments in the processing of increasingly complex refractory ores, new equipment and process routes. This new edition has been prepared by the prestigious J K Minerals Research Centre of Australia, which contributes its world-class expertise and ensures that this will continue to be the book of choice for professionals and students in this field.This latest edition highlights the developments and the challenges facing the mineral processor, particularly with regard to the environmental problems posed in improving the efficiency of the existing processes and also in dealing with the waste created. The work is fully indexed and referenced. - The classic mineral processing text, revised and updated by a prestigious new team- Provides a clear exposition of the principles and practice of mineral processing, with examples taken from practice- Covers the latest technological developments and highlights the challenges facing the mineral processor- New sections on environmental problems, improving the efficiency of existing processes and dealing with waste.

Front Cover 1

Title Page 4

Copyright Page 5

Table of Contents 6

Preface to 7th Edition 10

Contributors 11

Acknowledgements 12

Chapter 1 Introduction 14

Minerals and ores 14

Mineral processing methods 20

Efficiency of mineral processing operations 27

Concentration 29

Economics of tin processing 33

Economics of copper processing 36

Economic efficiency 39

References 41

Chapter 2 Ore handling 43

Introduction 43

The removal of harmful materials 43

Ore transportation 45

Ore storage 47

Feeding 49

References 51

Chapter 3 Metallurgical accounting, control and simulation 52

Introduction 52

Sampling and weighing the ore 52

Slurry streams 64

Automatic control in mineral processing 68

Neural networks 75

Circuit design and optimisation by computer simulation 76

Mass balancing methods 77

Introduction to mass balances on complex circuits 88

Design of experiments and plant trials 99

References 99

Chapter 4 Particle size analysis 103

Introduction 103

Particle size and shape 103

Sieve analysis 104

Sub-sieve techniques 110

References 120

Chapter 5 Comminution 121

Introduction 121

Principles of comminution 122

Comminution theory 123

Grindability 124

Simulation of comminution processes and circuits 125

References 128

Chapter 6 Crushers 131

Introduction 131

Primary crushers 132

Secondary crushers 139

Crushing circuits and control 152

References 156

Chapter 7 Grinding mills 159

Introduction 159

The motion of the charge in a tumbling mill 160

Tumbling mills 162

Grinding circuits 183

References 195

Chapter 8 Industrial screening 199

Introduction 199

Performance of screens 199

Factors affecting screen performance 201

Screen types 204

References 215

Chapter 9 Classification 216

Introduction 216

Principles of classification 216

Types of classifier 219

References 236

Chapter 10 Gravity concentration 238

Introduction 238

Principles of gravity concentration 238

Gravity separators 239

Jigs 240

Pinched sluices and cones 246

Spirals 249

Shaking tables 251

Pneumatic tables 254

Duplex concentrator 254

Mozley Laboratory Separator 255

Centrifugal concentrators 255

Gold ore concentrators 256

References 257

Chapter 11 Dense medium separation (DMS) 259

Introduction 259

The dense medium 260

Centrifugal separators 264

DMS circuits 267

Typical dense medium separations 268

Laboratory heavy liquid tests 270

Efficiency of dense medium separation 273

Construction of partition curves 274

Organic efficiency 277

References 278

Chapter 12 Froth flotation 280

Introduction 280

Principles of flotation 280

Classification of minerals 282

Collectors 283

Frothers 289

Regulators 290

The importance of pH 295

The importance of pulp potential 296

The role of bubble generation and froth performance 298

Entrainment 299

The engineering of flotation 300

Electroflotation 328

Agglomeration-skin flotation 329

Flotation plant practice 329

Reagents and conditioning 332

Control of flotation plants 333

Typical flotation separations 340

Flotation of copper ores 340

Oxidised copper ores 345

References 357

Chapter 13 Magnetic and electrical separation 366

Introduction 366

Magnetic separation 366

References 385

Chapter 14 Ore sorting 386

Introduction 386

Electronic sorting principles 386

Examples 387

References 390

Chapter 15 Dewatering 391

Introduction 391

Sedimentation 391

Filtration 403

Drying 410

References 411

Chapter 16 Tailings disposal 413

Introduction 413

Methods of disposal of tailings 413

References 420

Appendix 1 Metallic ore minerals 422

Appendix 2 Common non-metallic ores 434

Appendix 3 Excel spreadsheets for formulae in Chapter 3 441

Index 450

2 Ore handling

Introduction

Ore handling, which may account for 30–60% of the total delivered price of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to, or during, its various stages of treatment in the mill.

Since the physical state of ores in situ may range from friable, or even sandy material, to monolithic deposits with the hardness of granite, the methods of mining and provisions for the handling of freshly excavated material will vary extremely widely. Ore that has been well broken can be transported by trucks, belts, or even by sluicing, but large lumps of hard ore may need individual blasting. Modern developments in microsecond delay fuses and plastic explosive have resulted in more controllable primary breakage and easier demolition of occasional very large lumps. At the same time, crushers have become larger and lumps up to 2 m in size can now be fed into some primary units.

Open-pit ore tends to be very heterogeneous, the largest lumps often being over 1.5 m in diameter. The broken ore from the pit, after blasting, is loaded directly into trucks, holding up to 200 t of ore in some cases, and is transported directly to the primary crushers. Storage of such ore is not always practicable, due to its “long-ranged” particle size which causes segregation during storage, the fines working their way down through the voids between the larger particles; extremely coarse ore is sometimes difficult to start moving once it has been stopped. Sophisticated storage and feed mechanisms are therefore often dispensed with, the trucks depositing their loads directly into the mouth of the primary crusher.

The operating cycle on an underground mine is complex. Drilling and blasting are often performed on one shift, the ore broken in this time being hoisted to the surface during the other two shifts of the working day. The ore is transported through the passes via chutes and tramways and is loaded into skips, holding as much as 30 t of ore, to be hoisted to the surface. Large rocks are often crushed underground by primary breakers in order to facilitate loading and handling at this stage. The ore, on arrival at the surface, having undergone some initial crushing, is easier to handle than that from an open pit mine and storage and feeding is usually easier, and indeed essential, due to the intermittent arrival of skips at the surface.

The removal of harmful materials

Ore entering the mill from the mine (run-of-mine ore) normally contains a small proportion of material which is potentially harmful to the mill equipment and processes. For instance, large pieces of iron and steel broken off from mine machinery can jam in the crushers. Wood is a major problem in many mills as this is ground into a fine pulp and causes choking or blocking of screens, etc. It can also choke flotation cell ports, consume flotation reagents by absorption and decompose to give depressants, which render valuable minerals unfloatable.

Clays and slimes adhering to the ore are also harmful as they hinder screening, filtration, and thickening, and again consume valuable flotation reagents.

All these must be removed as far as possible at an early stage in treatment.

Hand sorting from conveyor belts has declined in importance with the development of mechanised methods of dealing with large tonnages, but it is still used when plentiful cheap labour is available.

Crushers can be protected from large pieces of “tramp” iron and steel by electromagnets suspended over conveyor belts (Figure 2.1). These powerful electromagnets can pick up large pieces of iron and steel travelling over the belt and, at intervals, can be swung away from the belt and unloaded. Guard magnets, however, cannot be used to remove tramp iron from magnetic ores, such as those containing magnetite, nor will they remove non-ferrous metals or non-magnetic steels from the ore. Metal detectors, which measure the electrical conductivity of the material being conveyed, can be fitted over or around conveyor belts. The electrical conductivity of ores is much lower than that of metals and fluctuations in electrical conductivity in the conveyed material can be detected by measuring the change that tramp metal causes in a given electromagnetic field.

Figure 1.1 Conveyor guard magnet

When a metal object causes an alarm, the belt automatically stops and the object can be removed. It is advantageous with non-magnetic ores to precede the metal detector with a heavy guard magnet which will remove the ferromagnetic tramp metals and thus minimise belt stoppages.

Large pieces of wood which have been “flattened out” by passage through a primary crusher can be removed by passing the ore feed over a vibrating scalping screen. Here the apertures of the screen are slightly larger than the maximum size of particle in the crusher discharge, allowing the ore to fall through the apertures and the flattened wood particles to ride over the screen and be collected separately.

Wood can be further removed from the pulp discharge from the grinding mills by passing the pulp through a fine screen. Again, while the ore particles pass through the apertures, the wood collects on top of the screen and can be periodically removed.

Washing of run-of-mine ore can be carried out to facilitate sorting by removing obscuring dirt from the surfaces of the ore particles. However, washing to remove very fine material, or slimes, of little or no value, is more important.

Washing is normally performed after primary crushing as the ore is then of a suitable size to be passed over washing screens. It should always precede secondary crushing as slimes severely interfere with this stage.

The ore is passed through high-pressure jets of water on mechanically vibrated screens. The screen apertures are usually of similar size to the particles in the feed to the grinding mills, the reason for which will become apparent.

In the circuit shown in Figure 2.2 material passing over the screen, i.e. washed ore, is transported to the secondary crushers. Material passing through the screens is classified into coarse and fine fractions by a mechanical classifier or hydrocyclone (Chapter 9) or both. It may be beneficial to classify initially in a mechanical classifier as this is more able to smooth out fluctuations in flow than is the hydrocyclone and it is better suited to handling coarse material.

Figure 1.2 Typical washing plant flowsheet

The coarse product from the classifier, designated “washing plant sands”, is either routed direct to the grinding mills or is dewatered over vibrating screens before being sent to mill storage. A considerable load, therefore, is taken off the dry crushing section.

The fine product from classification, i.e. the “slimes”, may be partially dewatered in shallow large diameter settling tanks known as thickeners (Chapter 15) and the thickened pulp is either pumped to tailings disposal or, if containing values, pumped direct to the concentration process, thus removing load from the grinding section. In the circuit shown, the thickener overflows are used to feed the high-pressure washing sprays. Water conservation in this manner is practised in most mills.

Wood pulp may again be a problem in the above circuit, as it will tend to float in the thickener, and will choke the water spray nozzles unless it is removed by retention on a fine screen.

Ore transportation

In a mineral processing plant, operating at the rate of 400,000 t d−1, this is equivalent to about 28 t of solid per minute, requiring up to 75 m3 min−1 of water. It is therefore important to operate with the minimum upward or horizontal movement and with the maximum practicable pulp density in all of those stages subsequent to the addition of water to the system. The basic philosophy requires maximum use of gravity and continuous movement over the shortest possible distances between processing units.

Dry ore can be moved through chutes, provided they are of sufficient slope to allow easy sliding, and sharp turns are avoided. Clean solids slide easily on a 15–25° steel-faced slope, but for most ores, a 45–55° working slope is used. The ore may be difficult to control if the slope is too steep.

The belt conveyor is the most widely used method of handling loose bulk materials. Belts now in use are with capacities up to 20,000 t h−1 and single flight lengths exceeding 15,000 m (“Bulk Materials Handling”, 2005), with feasible speeds of up to 10 m s−1.

The standard rubber conveyor belt has a foundation of sufficient strength to withstand the driving tension and loading strains. This foundation, which may be of cotton, nylon, or steel cord, is bound together with a rubber matrix and completely covered with a layer of vulcanised rubber.

The carrying capacity of the belt is increased by passing it over troughing idlers. These are support rollers set normal to the travel of the belt and inclined upward from the centre so as to raise the edges and give it a trough-like profile. There may be three or five in a set and they will be rubber-coated under a loading point, so as to reduce the wear and damage from impact. Spacing along the belt is at the maximum interval which avoids excessive sag. The return belt is supported by horizontal straight idlers which overlap the belt by a few inches at each...

| Erscheint lt. Verlag | 18.4.2011 |

|---|---|

| Sprache | englisch |

| Themenwelt | Sachbuch/Ratgeber ► Natur / Technik ► Natur / Ökologie |

| Naturwissenschaften ► Chemie | |

| Naturwissenschaften ► Geowissenschaften ► Geologie | |

| Naturwissenschaften ► Geowissenschaften ► Mineralogie / Paläontologie | |

| Technik ► Bauwesen | |

| Technik ► Bergbau | |

| Technik ► Maschinenbau | |

| ISBN-10 | 0-08-047947-2 / 0080479472 |

| ISBN-13 | 978-0-08-047947-7 / 9780080479477 |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich