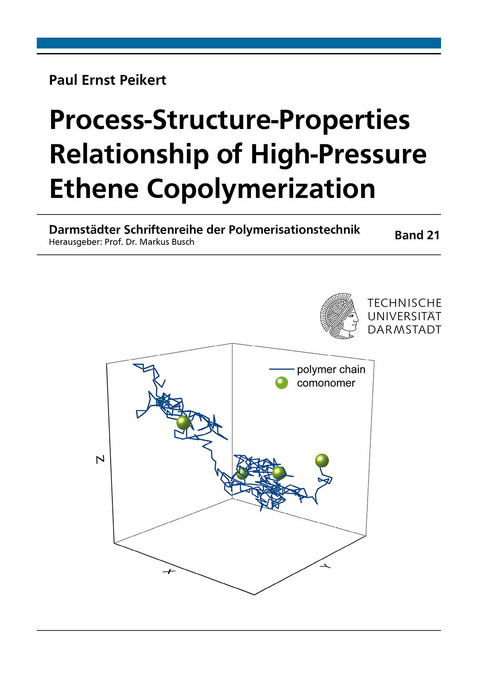

Process-Structure-Properties Relationship of High-Pressure Ethene Copolymerization

Seiten

Applying a second monomer enables to produce polymers with advanced properties. Within this work, several high-pressure mini-plant experiments have been conducted within a 100 mL autoclave in order to validate the kinetics of LDPE-copolymer systems with industrial relevance. Based on that, a multiscale modeling approach has been developed to derive microstructural information. In course of that, the exact branching structure as well as the monomer sequence of individual macromolecules can be elucidated. Subsequently, several algorithms have been developed in order to determine various product properties on basis of topology information. In addition to focus on sequence length distributions of comonomers and crystallinity behavior, a special focus has been placed on prediction of rheological properties of LDPE copolymer systems on industrial scale. By developing a 3D Self-Avoiding Random Walker with subsequent virtual size-exclusion chromatography, it was possible to identify strain-hardening behavior of LDPE homo- and copolymers, which is highly crucial for film blowing, with significant increased accuracy.Conclusively, the developed approach builds a bridge between chosen process conditions and resulting product properties in order to produce high-performance materials tailor-made for their application.

| Erscheinungsdatum | 07.01.2023 |

|---|---|

| Reihe/Serie | Darmstädter Schriftenreihe der Polymerisationstechnik ; 21 |

| Verlagsort | Düren |

| Sprache | englisch |

| Maße | 170 x 240 mm |

| Gewicht | 291 g |

| Themenwelt | Naturwissenschaften ► Chemie ► Organische Chemie |

| Schlagworte | EVA-copolymers • high-pressure polymerization • low-density polyethylene • Polymer Properties • rheology modeling |

| ISBN-10 | 3-8440-8895-4 / 3844088954 |

| ISBN-13 | 978-3-8440-8895-3 / 9783844088953 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

Mehr entdecken

aus dem Bereich

aus dem Bereich