Fundamentals of Additive Manufacturing

CRC Press (Verlag)

978-1-032-58263-4 (ISBN)

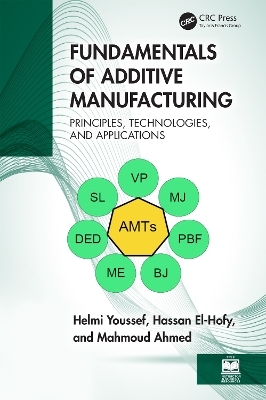

Additive manufacturing (AM) is a manufacturing process that has emerged as a viable technology for the production of engineering components. The aspects associated with additive manufacturing, such as less material wastage, ease of manufacturing, less human involvement, fewer tool and fixture requirements, and less post-processing, make the process sustainable for industrial use. Further, this new technology has led to highly optimized product characteristics and functional aspects. This textbook introduces the basics of this new additive manufacturing technology to individuals who will be involved in the grand spectrum of manufacturing finished products.

Fundamentals of Additive Manufacturing Technology: Principles, Technologies, and Applications provides knowledge and insight into various aspects of AM and deals with the basics, categories, materials, tooling, and equipment used. It presents a classified and complete description of the most common and recently developed additive manufacturing methods with applications, solved examples, and review questions. This textbook also emphasizes the fundamentals of the process, its capabilities, typical applications, advantages, and limitations, and also discusses the challenges, needs, and general recommendations for additive manufacturing.

This fundamental textbook is written specifically for undergraduates in manufacturing, mechanical, industrial, and materials engineering disciplines for courses in manufacturing technology taught in engineering colleges and institutions all over the world. It also covers the needs of production and manufacturing engineers and technologists participating in related industries. Additionally, the textbook can be used by students in other disciplines concerned with design and manufacturing, such as automotive, biomedical, and aerospace engineering.

Professor Helmi A. Youssef founded his scientific school in both Traditional and Non-traditional Machining Technologies based on several research and educational laboratories he built. In the early 1970s, he established the first NTM research laboratory at Alexandria University. Since that time, he carried out intensive research in his fields of specialization and supervised many Ph.D. and M. Sc. theses. Professor Youssef has organized and participated in many international conferences. He has published many scientific papers in specialized journals and authored many books in his fields of specialization, two of which are singly authored. Currently, Professor Youssef is an emeritus Professor in PED, at Alexandria University. His work involves developing courses and conducting research in the areas of metal cutting and nontraditional machining. Professor Hassan El-Hofy has published over 90 scientific and technical papers and has supervised many graduate students in advanced machining. He serves as a consulting editor for many international journals and is a regular participant in many international conferences. Between August 2007, and July 2010 he was the chairperson of the Department of Production Engineering, AU. In October 2011 he was selected as the Vice Dean for Education and Student Affairs College of Engineering, AU. Between December 2012 and February 2018, he was the Dean of the Innovative Design Engineering (IDE) School at the Egypt-Japan University of Science and Technology (E-JUST) in Alexandria, Egypt. He worked as an acting Vice President of Research from December 2014 to April 2017 at E-JUST. Currently, he is a professor of machining technology at the Department of Industrial and Manufacturing Engineering (IME) at E-JUST, Egypt. Professor M. Hamed Ahmed constructed and taught numerous graduate and undergraduate courses in the general fields of materials and manufacturing, to name a few; Failure Analysis, Material Selection, Finite Element Analysis, Fracture Mechanics, Non-destructive Testing, Advanced Manufacturing Processes, Theory of Plasticity, Solid Mechanics, Die Design, Metal Forming, Metal Cutting, Non-conventional Machining, Welding Technology, Engineering Materials, and Manufacturing Technology. Professor Ahmed took part in establishing and developing laboratories in the same fields including The Material Technology Lab. (Alex. University), Material Testing, Forming Machines, CNC Machining, Metrology, and Electroplating Labs. (UAE University), as well as Non-conventional Machining, and CNC Machining Labs. (King Abdul-Aziz University, KSA). Over the years, Professor Ahmed has supervised numerous M.Sc. and Ph.D. degrees, covering the areas of Electro-Discharge Machining, Failure of Welded Joints, Extrusion of Fluted Sections, Plasma Cutting, Ultrasonic Machining, Pulsed Current MIG Welding, Compression of Tubular Sections, Forward Tube Spinning, Characterization of Engineering Materials Using Nodal Analysis, Selection of Non-Traditional Machining Processes, Thermo-mechanical Rolling, Functionally Graded Metal Matrix Composites, Manufacturing of Porous Metals and AM Assisted Manufacturing. Prof. Ahmed has a good track record of publishing in numerous national and international conferences and reputable journals. He also contributed to the development and improvement of industrial activities within Alexandria through consultations related to solving design and manufacturing problems, material and product inspection, failure analysis, plant layouts, feasibility and opportunity studies, as well as running crash and training courses in the relevant fields of interest.

1. Introduction to Additive Manufacturing. 2. Software Aspects for Additive Manufacturing. 3. Basic Additive Manufacturing Techniques. 4. Technologies of Additive Manufacturing of Polymers and Composites. 5. Technologies of Additive Manufacturing of Metallic Materials. 6. Technologies for Additive Manufacturing of Ceramics (AMC). 7. Feedstock Materials for Additive Manufacturing Processes. 8. Post-Processing Techniques in Additive Manufacturing Processes. 9. Design for Additive Manufacturing. 10. Impact of Additive Manufacturing on Conventional Manufacturing Processes. 11. Manufacturing Cost of Additive Manufacturing. 12. Environmental and Health Impacts of Additive Manufacturing. 13. Fields of Application of Additive Manufacturing. 14. Additive Manufacturing Characterization, Challenges and Needs, Future Trends and Final Recommendations. 15. Additive Manufacturing Case Studies.

| Erscheinungsdatum | 25.07.2024 |

|---|---|

| Zusatzinfo | 42 Tables, black and white; 162 Line drawings, black and white; 83 Halftones, black and white; 245 Illustrations, black and white |

| Verlagsort | London |

| Sprache | englisch |

| Maße | 156 x 234 mm |

| Gewicht | 993 g |

| Themenwelt | Medizin / Pharmazie ► Physiotherapie / Ergotherapie ► Orthopädie |

| Technik ► Medizintechnik | |

| Technik ► Umwelttechnik / Biotechnologie | |

| ISBN-10 | 1-032-58263-4 / 1032582634 |

| ISBN-13 | 978-1-032-58263-4 / 9781032582634 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich