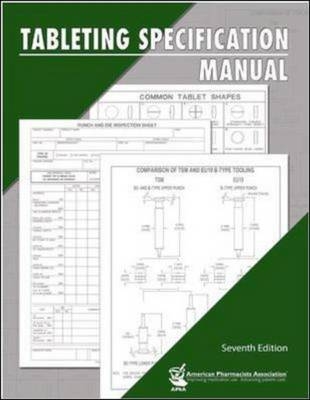

Tableting Specification Manual

American Pharmacists Association (Verlag)

978-1-58212-078-2 (ISBN)

- Titel erscheint in neuer Auflage

- Artikel merken

The Tableting Specification Manual covers every facet of tablet manufacturing: tooling and tablet design, tooling steels, maximum compression forces, tooling inspection and maintenance, and troubleshooting of tablet and tool production problems. This reference helps users increase tablet quality and production rate, extend tooling life, prevent damage to presses, and avoid costly work stoppages.

Key Features:

Official change of barrel diameter of B-type (0.748 [19.00]) and D-type (0.998 [25.35]) lower punches to match diameter of upper punch barrels.

Discussion of automated high-throughput presses and high-performance standards.

Recommendation of a barrel-to-neck chamfer for all upper and lower punches.

Recommendation of domed head for new punches.

Tooling options: rotating punch heads, multiple tip punches, dust cups, bellows.

Torque values for screws used to assemble keys.

Comprehensive listing of new press models (in appropriate tooling interchangeability tables).

Discussion of and function ratings for tooling coatings and treatments.

Discussion of available systems for electronic inspection of tooling.

Expanded definitions of industry terminology.

Other Key Features:

Tablet tooling specifications and tooling design options

Guidelines for optimal tablet design

Punch tip compression forces

Comprehensive guidelines on tooling maintenance

Troubleshooting guides for tablet production problems

The Tableting Specification Manual Steering Committee is made up of 11persons who represent the three main branches of the tablet manufacturing industry: tooling manufacturers/distributors, press manufacturers/distributors, and pharmaceutical companies. Each member has years of hands-on experience in one or more of these areas. The committee has worked diligently to further the worldwide implementation of standardized tooling specifications. In addition, there are 9 reviewers and contributors to the Manual.

•List of Figures

•List of Tables

•Acknowledgments

•Preface

•Introduction

Section 1: Guidelines for Using this Manual•Tooling Terminology

•Tablet Manufacturing

•Tooling Specifications

•Standardization: Its Purpose and Advantages

Section 2: TSM Tooling Specifications and Design Options•Effect of Tooling Dimensions on Tablet Manufacturing

•Revised Tooling Specifications

•Tooling Design Options

•TSM Compatibility of International Presses

•Tooling Specification Figures and Tables (Index)

Section 3: Tablet Design•Tablet Terminology

•Tablet Identification

•Tablet Printing

•Tablet Detail Drawings

•Tablet Land

Section 4: Tool Steels, Compression Forces, and Fatigue Failure•Tool Steels

•Chemical Composition of Steels

•Hardness of Tool Steels

•Punch Tip Force Ratings

•Fatigue Failure of Punch Tips

Section 5: Tooling Procurement, Inspection, and Maintenance•Standard Operating Procedures

•Punch and Die Maintenance

Section 6: Troubleshooting Tablet Production Problems•Advantages of Quality Tooling

•Tablet Problems

•Tooling Problems

•Turret Guideway Wear

Appendix•Tablet Press and Tooling Manufacturers and Distributors

| Erscheint lt. Verlag | 16.1.2006 |

|---|---|

| Zusatzinfo | Illustrations |

| Verlagsort | Washington |

| Sprache | englisch |

| Maße | 218 x 277 mm |

| Gewicht | 413 g |

| Themenwelt | Medizin / Pharmazie ► Pflege |

| Medizin / Pharmazie ► Pharmazie ► PTA / PKA | |

| ISBN-10 | 1-58212-078-1 / 1582120781 |

| ISBN-13 | 978-1-58212-078-2 / 9781582120782 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich