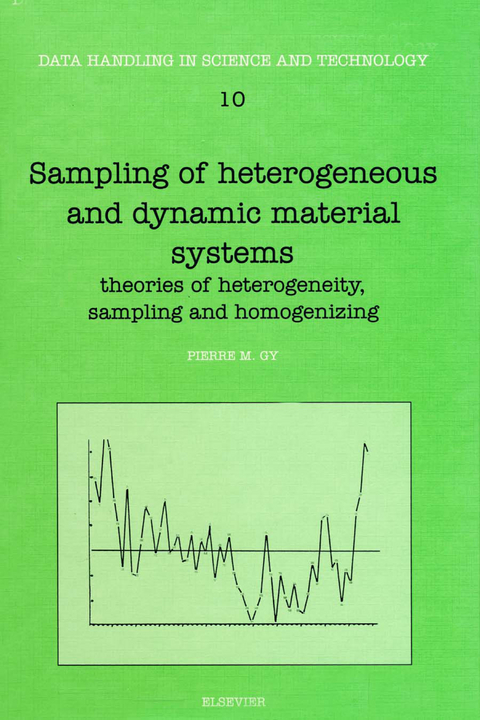

Sampling of Heterogeneous and Dynamic Material Systems (eBook)

652 Seiten

Elsevier Science (Verlag)

978-0-08-086837-0 (ISBN)

The scope covers the derivation of theories of probabilistic sampling and of bed-blending from a complete theory of heterogeneity which is based on an original, very thorough, qualitative and quantitative analysis of the concepts of homogeneity and heterogeneity. All sampling errors result from the existence of one form or another of heterogeneity. Sampling theory is derived from the theory of heterogeneity by application of a probabilistic operator to a material whose heterogeneity has been characterized either by a simple scalar (a variance: zero-dimensional batches) or by a function (a variogram: one-dimensional batches). A theory of bed-blending (one-dimensional homogenizing) is then easily derived from the sampling theory.

The book should be of interest to all analysts and to those dealing with quality, process control and monitoring, either for technical or for commercial purposes, and mineral processing.

Although this book is primarily aimed at graduates, large portions of it are suitable for teaching sampling theory to undergraduates as it contains many practical examples provided by the author's 30-year experience as an international consultant. The book also contains useful source material for short courses in Industry.

Although sampling errors inevitably lead to analytical errors, the importance of sampling is often overlooked. The main purpose of this book is to enable the reader to identify every possible source of sampling error in order to derive practical rules to (a) completely suppress avoidable errors, and (b) minimise and estimate the effect of unavoidable errors. In short, the degree of representativeness of the sample can be known by applying these rules. The scope covers the derivation of theories of probabilistic sampling and of bed-blending from a complete theory of heterogeneity which is based on an original, very thorough, qualitative and quantitative analysis of the concepts of homogeneity and heterogeneity. All sampling errors result from the existence of one form or another of heterogeneity. Sampling theory is derived from the theory of heterogeneity by application of a probabilistic operator to a material whose heterogeneity has been characterized either by a simple scalar (a variance: zero-dimensional batches) or by a function (a variogram: one-dimensional batches). A theory of bed-blending (one-dimensional homogenizing) is then easily derived from the sampling theory. The book should be of interest to all analysts and to those dealing with quality, process control and monitoring, either for technical or for commercial purposes, and mineral processing. Although this book is primarily aimed at graduates, large portions of it are suitable for teaching sampling theory to undergraduates as it contains many practical examples provided by the author's 30-year experience as an international consultant. The book also contains useful source material for short courses in Industry.

Front Cover 1

Sampling of Heterogeneous and Dynamic Material Systems: Theories of Heterogeneity, Sampling and Homogenizing 4

Copyright Page 5

TABLE OF CONTENTS 6

FOREWORD 32

Relationship between the three components of the sub-title 32

Validity of this set of theories and origin of the matter 33

Validity of these theories and physical state of the matter 34

Historical summary 35

Acknowledgments 38

FIRST PART: GENERAL INTRODUCTION 39

What is new in this book ? 39

Characterization of the various forms of heterogeneity 40

Generalization of the heterogeneity carried by a unit 40

Emphasis put on sampling correctness 42

Structure and circumstances * correctness and accuracy 42

Point-by-point computation of auxiliary functions, error-generating functions and sampling variances 43

Estimation of a mass or a volume by proportional sampling 44

Theory of one-dimensional homogenizing or "Bed-blending" 45

Message to the hurried reader 45

CHAPTER 1. BASIC DEFINITIONS AND NOTATIONS 47

1.1. Introduction 47

1.2. Terminology defining the material under investigation 47

1.3. Homogeneity and heterogeneity of the material under investigation 49

1.4. Sampling 50

1.5. Analysis 52

1.6. Statistical definitions and notations 52

1.7. How to qualify the properties of a single selection operation or of an entire sampling procedure 53

1.8. Structure and circumstances * Correctness and accuracy 56

1.9. Objectives of a sampling theory 58

1.10. Requirements of the user of sampling equipment 58

1.11. System of notation 59

1.12. Tonnes and tons 62

CHAPTER 2. LOGICAL STRUCTURE OF THIS SET OF THEORIES 63

2.1. First part (chapters 1 and 2) * General introduction 63

2.2. Second part (chapters 3 to 5) * Heterogeneity 63

2.3. Third part (chapters 6 to 8) * General analysis of the sampling concept 65

2.4. Fourth part (chapters 9 to 12) * Achievement of sampling correctness 66

2.5. Fifth part (chapters 13 to 16) * One-dimensional sampling model 68

2.6. Sixth Part (chapters 17 to 21) * Zero-dimensional sampling model 69

2.7. Seventh part (chapters 22 and 23) * Sampling by splitting 71

2.8. Eighth part (chapters 24 to 29) * Practical resolution of sampling problems 71

2.9. Ninth part (chapters 30 to 33) * Sampling for commercial purposes * specific problems 73

2.10. Tenth part (chapters 34 and 35) * Homogenizing 74

SECOND PART: HETEROGENEITY 75

Heterogeneity in the laboratory and the pilot plant 75

Heterogeneity in the production plant 76

Heterogeneity and marketing of the final products 77

Heterogeneity in biology and medicine 77

Homogeneity and heterogeneity of human populations 78

CHAPTER 3. LOGICAL ANALYSIS OF THE CONCEPTS OF HOMOGENEITY AND HETEROGENEITY 79

3.1. Qualitative analysis of the duality homogeneity/ heterogeneity 79

3.2. Classification of batches of particulate matter 82

3.3. Functional, random and stochastic relationships 84

3.4. Census of the cases studied in this book 85

CHAPTER 4. HETEROGENEITY OF A POPULATION OF UNITS COMPOSING A ZERO-DIMENSIONAL BATCH 87

4.1. Introduction and notations 87

4.2. Heterogeneity of a population of unspecified units Um 88

4.3. Case of a population of fragments Fi 91

4.4. Case of a population of NG groups Gn of fragments Fi 92

4.5. Heterogeneity hm and imaginary content a`m of unit Um 104

4.6. Computation of CHL and HIL * Set of enumerable units 105

4.7. Estimation of the heterogeneity invariant HlL * Non-enumerable units 108

4.8. Estimation of the heterogeneity invariant HIL * practical expression 113

4.9. Application to non-mineral materials 124

4.10 Simplified expression of HIL * Practical implementation 125

4.11. Heterogeneity invariant HIL * Experimental estimation 127

4.12. Range covered by the heterogeneity invariant HIL 132

4.13. Physical meaning of the heterogeneity invariant HIL 133

CHAPTER 5. HETEROGENEITY OF A SERIES OF UNITS COMPOSING A ONE-DIMENSIONAL BATCH 134

5.1. Introduction and notations 134

5.2. Characterization of the heterogeneity of batch L 136

5.3. Global heterogeneity of a series of units 137

5.4. Sequential heterogeneity of a series of units 137

5.5. Modelling of the experimental variogram 144

5.6. Auxiliary Functions of the variogram 152

5.7. Error–generating functions 156

5.8. Point–by–point computation of auxiliary and error–generating functions 158

5.9. Typical examples of chronovariograms and of their auxiliary functions 164

5.10. Practical implementation of the variogram 173

5.11. Organization of a variographic experiment 175

5.12. Autocorrelation and breaking up of hm into a sum of components 177

5.13. Autocorrelation and general shape of the variogram 179

THIRD PART: GENERAL ANALYSIS OF THE CONCEPT OF SAMPLING 182

Why does one sample ? 182

Sampling and selection * Sampling in the wider and in the strict sense 182

Summary of the logical structure of estimation process 183

Logical consequences of this logical analysis 183

The unreal hypothesis of homogeneity and its dangers 183

The wishful thinker's biased approach 183

The scientist's undisputable logical approach 184

Sampling errors and sampling theory 184

Financial consequences of sampling errors 185

Divergent developments of sampling and analysis 186

To teach or not to teach the sampling theory 187

Heterogeneity and the sampling theory 187

Message to the reader interested in practice 187

Organization of the part of this book dedicated to sampling 188

CHAPTER 6. RESPECTIVE ROLES OF SAMPLING, PREPARATION AND ANALYSIS 189

6.1 Quality control in research, industry and trade of bulk commodities 189

6.2 Can quality control be directly carried out on the batch to be valued ? 189

6.3 Can the assay–portion be directly extracted from batch? 190

6.4 Mass reduction stages and preparation stages 190

6.5 Successive estimators and final estimate of the lot critical content 191

6.6 Cumulative nature of the components of the global estition error GE 193

6.7 Conclusions concerning the respective roles of sampling and analysis 193

6.8 Recapitulation 193

CHAPTER 7. CRITICAL REVIEW OF THE MAIN SELECTION SCHEMES AND PROCESSES 194

7.1. Introduction to a classification of sampling processes and methods 194

7.2. Critical review of non-probabilistic selection processes 195

7.3. Probabilistic sampling of small or valuable batches 198

7.4. Probabilistic sampling of unmovable batches 199

7.5. Probabilistic sampling of batches during their transfer under the form of a set of discrete units 199

7.6. Probabilistic sampling of batches during their transfer under the form of a continuous flowing stream 200

7.7. Selection modes within batches reducible to a zero- or one-dimensional set of discrete units 204

7.8. Selection modes within batches reducible to a one–dimensional continuous set 208

7.9. Comparison between the increment sampling and splitting processes 213

7.10. Recapitulation 221

CHAPTER 8. COMPLEMENTARY MODELS OF THE INCREMENT SAMPLING PROCESS 224

8.1. Introduction to a group of probabilistic sampling models 224

8.2. Presentation of the continuous model of increment sampling 226

8.3. Particular case of the one-dimensional time model 231

8.4. Presentation of the discrete model of sampling 233

8.5. Objective pursued when developing a sampling model 234

8.6. Resolution of sampling problems 235

FOURTH PART: ACHIEVEMENT OF SAMPLING CORRECTNESS 237

Additional errors involved when reality deviates from model 237

Sampling is the Analysts' huge blind spot 239

CHAPTER 9. FROM MODEL POINT-SAMPLE TO PREPARED-SAMPLE ACTUALLY COLLECTED * GENERATION OF MATERIALIZATION ERRORS ME 240

9.1. The double function of a cross-stream sampler 240

9.2. Obtention of the prepared increments and sample 240

9.3. Logical breaking up on the scale of an increment 240

9.4. Point - increment IP 241

9.5. Correctly-delimited-increment ID 242

9.6. Incorrectly-delimited-increment I ' D . 243

9.7. Correctly-extracted-increment IE 244

9.8. Incorrectly-extracted-increment I ' E 245

9.9. Correctly-transferred-increment IT 246

9.10 Incorrectly-transferred (and prepared) increment I't 246

9.11 Recapitulation of the materialization errors ME 247

9.12 Probabilistic approach to selection, delimitation and extraction 248

9.13 Generalization to two- and three-dimensional objects 250

9.14. Particular case of liquid batches 251

CHAPTER 10. CONDITIONS OF CORRECT INCREMENT DELIMITATION GENERATION OF THE DELIMITATION ERROR DE 252

10.1. Definition of a correct increment delimitation 252

10.2. Irreducible three-dimensional objects 252

10.3 Two-dimensional objects 257

10.4. Spatial one-dimensional objects 265

10.5. Temporal one-dimensional objects * flowing streams 269

10.6. Cross-stream samplers * conditions of delimitation correctness involving the cutter geometry 270

10.7. Cross-stream samplers * conditions of delimitation correctness involving the cutter kinetics 278

10.8. Cross-stream samplers * conditions of delimitation correctness involving the sampler lay-out 282

10.9. Particular case of high and very high flow-rates 285

10.10. Cross-stream samplers * recapitulation of the conditions of correct delimitation 286

10.11. Cost of a correct delimitation 286

10.12. Possibility of estimating delimitation bias m(DE) 286

CHAPTER 11. CONDITIONS OF CORRECT INCREMENT EXTRACTION * GENERATION OF THE EXTRACTION ERROR EE 288

11.1. Definition of a correct increment extraction 288

11.2. Essence of the problem * case of particulate solids 288

11.3. Essence of the problem * case of liquids 289

11.4. Case of particulate solids * conditions of extraction correctness involving the material sampled 290

11.5. Case of particulate solids * conditions of extraction correctness involving the cutter 291

11.6. Cutter width and velocity * experimental estimation of critical values 302

11.7. Cost of correct extraction 310

11.8. Respect of the increment and sample integrity 310

11.9. Curves of extraction probability 310

11.10. Example of extraction error observed when drilling a two- or three-dimensional orebody 311

11.11. Recapitulation of rules of extraction correctness 312

CHAPTER 12. CONDITIONS OF INCREMENT AND SAMPLE CORRECT PREPARATION GENERATION OF THE PREPARATION ERRORS PE 313

12.1. Introduction * purpose of preparation operations 313

12.2. Census of the preparation errors 314

12.3. Contamination of increments and sample 315

12.4. Loss of elements belonging to increments and sample 318

12.5. Alteration of chemical composition of the material 323

12.6. Alteration of physical composition of the material 326

12.7. Unintentional operational mistakes 329

12.8. Deliberate tampering with samples or with analytical results 329

12.9. Recapitulation and conclusions 331

FIFTH PART : ONE-DIMENSIONAL SAMPLING MODEL 332

* The continuous perspective 332

* The discrete or discontinuous perspective 332

CHAPTER 13. ONE-DIMENSIONAL SAMPLING MODEL * GENERATION OF THE INTEGRATION ERROR IE 334

13.1. Introduction 334

13.2 Development of the one-dimensional model * Definitions and notations 335

13.3. Characterizing of the heterogeneity of the lot L * New approach 337

13.4. The sampling process and the sample S 338

13.5 Integration error I E * introduction 339

13.6. Mean of the distribution of integration error IE 340

13.7. Variance of the distribution of integration error IE 340

13.8 Breaking up of the total integration error IE 342

13.9. Examples of computation of sampling errors * role of measurement errors in an experimental variogram 344

13.10. Example No 1 * Feed to the bed-blending system of a cement factory 345

13.11. Example No 2 * feed to a uranium leaching plant 348

13.12. Example No 3 * unloading of a zinc concentrate * moisture content 351

13.13 Example No 4 * unloading of a zinc concentrate * Zinc % 352

13.14 Example No 5 * control of fraction < 0.5 mm in a coal

13.15 Remark 356

CHAPTER 14. DISCONTINUITY COMPONENT IEi OF THE INTEGRATION ERROR IEi 357

14.1. Introduction 357

14.2. From component ai (t) of a (t) to component IEi of IE 357

14.3. Properties of the expected value m(IEi ) 359

14.4. Properties of the variance s2 (IEi ) 359

14.5. Conditions of cancellation of the variance s2 ( IEi) 360

14.6. Minimizing of the variance s2 (IEi) 361

14.7. Particular case of liquids 363

14.8. Breaking up of IEi into a sum of two components 363

CHAPTER 15. CONTINUOUS COMPONENT IE OF THE INTEGRATION ERROR IE 364

15.1. Introduction 364

15.2. From component a2 (t) of a (t) to component IE2 of IE 364

15.3. Properties of the expected value m (IE2) 366

15.4. Properties of the variance s2 (IE2) 366

15.5. Conditions of cancellation of the variance s2 (IE2) 367

15.6. Minimizing of the variance s2 (IE2) 369

CHAPTER 16. PERIODIC COMPONENT IE3 OF THE INTEGRATION ERROR IE 371

16.1. Introduction 371

16.2. Preliminary observations 371

16.3. Frequency of observation of cyclic phenomena 373

16.4. Origin of the cyclic fluctuations observed 374

16.5. Properties of the integration error IE3 377

16.6. Practical comparison of the three selection modes 379

16.7. Practical recommendations 380

SIXTH PART: ZERO-DIMENSIONAL SAMPLING MODEL 381

* THE CONTINUOUS PERSPECTIVE 381

* THE DISCRETE OR DISCONTINUOUS PERSPECTIVE 381

CHAPTER 17. ZERO-DIMENSIONAL MODEL * GENERAL CASE * TOTAL ERROR TE 383

17.1. Notations * introduction 383

17.2. Distribution of random variables pem, Nk, Mk, Ak, ak 384

17.4. Distribution of critical content ak and of total error TE 386

17.5. Total error TE * case of a correct selection 392

17.6. Concepts of selection probability and of sampling ratio * probabilistic model and equiprobable model 394

17.7. Breaking up of the correct sampling error CE 397

17.8. Zero-dimensional discrete model * Incorrect probabilistic selection 398

CHAPTER 18. LINKING UP ZERO- AND ONE-DIMENSIONAL MODELS 399

18.1. Introduction * objectives of the current chapter 399

18.2. Hypothesis of a correct selection and consequences 399

18.3. Continuous one-dimensional model * predominance of the discontinuity component on the scale of particles 400

18.4. Comparison of the errors IE = IEi (continuous model) and CE (discreate model ) 400

18.5. Logical analysis and breaking up of the discontinuity error CE 402

CHAPTER 19. DEFINITION AND PROPERTIES OF THE FUNDAMENTAL ERROR FE 405

19.1. Reminder and definition 405

19.2. Possibility of cancelling the fundamental error FE 405

19.3. Minimizing the fundamental bias m(FE) 407

19.4. Minimizing the fundamental variance s2 (FE) 407

19.5. Resolution of problems involving fundamental variance 408

19.6. Estimation of the fundamental variance s2 (FE) 409

19.7. Estimation of minimum sample mass to be extracted from batch L 411

19.8. Particulate solid sampling * estimation of the maximum fragment size do, knowing the tolerated variance so2 (FE) and the sample mass Mso, 415

19.9. Concept of intrinsic fundamental variance of batch L 417

19.10. Concept of minimum mass of matter characterized by an invariant HIL 418

CHAPTER 20. DEFINITION AND PROPERTIES OF THE GROUPING AND SEGREGATION ERROR GSE 419

20.1. Reminder and definition 419

20.2. Cancelling out of grouping and segregation error GSE 420

20.3. Minimizing of the grouping and segregation error GSE 421

20.4. Practical resolution of problems involving the grouping and segregation variance 422

CHAPTER 21. PROBABILISTIC BUT INCORRECT SAMPLING * TOTAL ERROR TE 424

21.1. Reminder and definition 424

21.2. Factors susceptible of altering selection probability 424

21.3. Expression of moments of the total sampling error TE 425

21.4. Estimation of moments of total sampling error TE 427

21.5. Curves of extraction probabilities 427

21.6. Estimation of extraction probabilities 429

21.7. Examples of extraction biases and variances 432

21.8. Conclusions 434

PART 7: SAMPLING BY SPLITTING 437

CHAPTER 22. REVIEW OF MAIN SPLITTING METHODS AND DEVICES 439

22.1. Reminder * logical breaking up of splitting process 439

22.2. Practical implementation of the four steps of the splitting process 441

22.3. True and degenerate splitting processes 443

22.4. Coning and quartering or "Cornish quartering" 444

22.5. Fractional and alternate shovelling 446

22.6. Sample reduction methods involving two-and one-dimensional models 450

22.7. Riffle splitter 453

22.8. Sectorial dividers 455

22.9. Specimen-taking devices * particular case of automatic assay-portion feeders associated to laboratory scales 458

CHAPTER 23. SPLITTING ERRORS 459

23.1. Correctness of splitting methods and devices 459

23.2. Splitting equity * Louis-le-Debonnaire's splitting method 460

23.3. Incorrect implementation of a correctly built riffle splitter 460

23.4. Splitting in the light of the two complementary sampling models 463

23.5. Estimation of splitting variance * zero-dimensional model 463

23.6. Estimation of splitting variance * one-dimensional model 464

23.7. How to solve the problems involving the splitting variance practically 464

EIGHTH PART: RESOLUTION OF SAMPLING PROBLEMS 465

CHAPTER 24. PROPERTIES OF THE COMPONENTS OF THE TOTAL SAMPLING ERROR * RECAPITULATION 467

24.1. Logical analysis of the global estimation error 467

24.2. Fundamental error FE 473

24.3. Grouping and segregation error GSE 476

24.4. Discontinuity component IEi of integration error IE 478

24.5. Non-periodic, continuity component IE2 of the integration error IE 480

24.6. Periodic component IE3 of the integration error IE 482

24.7. Increment delimitation error DE 484

24.8. Increment Extraction error EE 486

24.9. Increment and sample preparation errors PE 488

24.10 Conclusions * Questions * Recommendations 489

CHAPTER 25. SOLVABLE AND UNSOLVABLE SAMPLING PROBLEMS 491

25.1. Definition of a solvable sampling problem 491

25.2. Estimation and sampling reproducibility 493

25.3. Notion of acceptable sampling cost 494

25.4. Sampling of irreducible three-dimensional objects 497

25.5. Sampling of two-dimensional objects 499

25.6. Sampling of spatial one-dimensional objects 501

25.7. Sampling temporal one-dimensional objects (streams) 503

25.8. Sampling of zero-dimensional objects 503

25.9. Sampling of batches of manageable bulk 504

25.10. Problems specific to the sampling of liquids and liquid-solid systems 505

25.11. Possibilities of correct sampling * all objects * solvable and unsolvable problems * recapitulation 512

CHAPTER 26. WORKING OUT OF A SAMPLING SCHEME 513

26.1. Definition of a sampling scheme 513

26.2. Particulate solids * graphical representation of a sampling scheme 513

26.3. Representativeness of the final sample * repartition of the total acceptable sampling variance so2 (TEi between the different stages 515

26.4. Design of a completely automatic particulate solid sampling plant 517

26.5. Double function of a sampling plant 519

26.6. Graphic resolution of a sampling problem 520

26.7. Choice of the comminution stages and devices 523

26.8. Examples of safe sampling schemes 524

26.9. Examples of unsafe sampling schemes 529

26.10. Variants of the simple safety line of figure 26.2. 533

26.11. Particular case of materials containing precious minerals and metals 534

26.12. Much debated question of ABSOLUTE minimum increment mass 540

26.13. Minimum mass Ms o of the sample S 542

26.14. Minimum number Qo of increments in the sample S 542

26.15. Conclusions 543

CHAPTER 27. SAMPLING FOR A MOISTURE ANALYSIS AND FOR THE COMPUTATION OF A DRY TONNAGE 544

27.1. Introduction 544

27.2. Definition of the moisture of a wet particulate solid 544

27.3. Mineral materials * possible definitions of a moisture content 546

27.4. Moisture estimation for technical purposes 546

27.5. Estimation of mass of component A in a wet batch LW 548

27.6. Theoretical approach of sampling for moisture estimation 556

27.7. General practical recommendations 558

CHAPTER 28. SAMPLING PARTICULATE SOLID FOR A SIZE ANALYSIS 559

28.1. Concepts of size of a fragment and of size analysis 559

28.2. True unknown size distribution of a batch L of particulate solids 560

28.3. True unknown size distribution of a sample S 561

28.4. Estimated size distribution of a sample S 562

28.5. Sampling errors at the light of two existing models 563

28.6. Fundamental error attached to a size distribution 563

28.7. Example of estimation of heterogeneity invariant HIL 565

28.8. Resolution of sampling problems involving the size analysis 566

CHAPTER 29. MASS AND/OR VOLUME ESTIMATION BY PROPORTIONAL SAMPLING 569

29.1. Definition of proportional sampling 569

29.2. Critical review of the conventional bulk material continuous weighing and volume measuring systems 570

29.3. Mass and time sampling ratios * selection probability 574

29.4. Choice of a reliable proportional sampler 576

29.5. Practical considerations 582

29.6. Experimental study of proportional sampling 584

29.7. Reproducibility of proportional sampling 592

29.8. Provisional conclusions concerning the estimation of masses and volumes by proportional sampling 593

NINTH PART: SAMPLING FOR COMMERCIAL PURPOSES SPECIFIC PROBLEMS 594

CHAPTER 30. CHECK ON SAMPLING CORRECTNESS vs. CHECK ON SAMPLING ACCURACY * THE REASONING ERRORS 596

30.1. Introduction 596

30.2. Structural and circumstantial properties * a reminder 597

30.3. Practical advantages of the check on correctness 599

30.4. Pitfalls, drawbacks and dangers of check on accuracy 599

30.5. Conclusions 600

CHAPTER 31. COMMERCIAL SAMPLING AND ANALYSIS * REFLEXIONS ON THE SPLITTING LIMIT PROCEDURE 602

31.1. Purpose and description of splitting limit procedure 602

31.2. Notations 603

31.3. Discussion of the procedure 604

31.4. Practical examples 605

31.5. Now what could be done ? 608

31.6. Particular case of long-term commercial contracts 609

CHAPTER 32. COMMERCIAL SAMPLING AND ANALYSIS * TESTING THE LONG-TERM AGREEMENT BETWEEN SELLER AND BUYER 610

32.1. Generality of the problem 610

32.2. Introduction to a double student-fisher test 611

32.3. Notations and definitions 614

32.4. Preliminary test or test of hypothesis H` = [D` = 0) 615

32.5. Complementary tests 617

32.6. Recapitulation of the conclusions of the three tests 623

32.7. Practical implement. and Graphical represent. of the test 625

32.8. Example 626

32.9. Average number of trials necessary to disclose a given systematic difference 631

CHAPTER 33. CHECK ON THE SAMPLING BIAS * AGREEMENT BETWEEN THE ESTIMATE OF A CONTENT AND THE TRUE VALUE 632

33.1. The bias test * introduction and notations 632

33.2. How to obtain a reference estimator ZN of the unknown content XN of LN 633

33.3 Example of application of method No 2 637

33.4. When reproducibility is mistaken for accuracy 641

TENTH PART: HOMOGENIZING 643

Why does one homogenize ? 643

First strategy * acceptance of heterogeneity as inevitable 644

Second strategy * suppressing or minimizing heterogeneity 644

How does one homogenize ? 645

CHAPTER 34. CENSUS OF THE HOMOGENIZING PROCESSES 647

34.1. Classification of the homogenizing processes 647

34.2. Discontinuous static processes 648

34.3. Continuous static processes * The shifting mean model 648

34.4. Batch dynamic homogenizing processes 650

34.5. Batch dynamic processes based on pumping of a liquid or pneumatic transfer of a powder in closed circuit 652

34.6. Continuous dynamic processes based on pumping of liquid or pneumatic transfer of powder in semi-closed circuit 652

34.7. Case of the rod- and ball-mills 652

CHAPTER 35. ONE-DIMENSIONAL HOMOGENIZING OR BED-BLENDING 654

35.1. Introduction 654

35.2. Description of a bed-blending system 654

35.3. Model of the one-dimensional homogenizing process 655

35.4. Development of a theory fitting this model 656

35.5. Experimental check of the theoretical conclusions 660

35.6. Input variogram 662

35.7. Output variogram 667

35.8. Conclusion 673

USEFUL REFERENCES 674

INDEX 678

| Erscheint lt. Verlag | 23.10.1992 |

|---|---|

| Sprache | englisch |

| Themenwelt | Mathematik / Informatik ► Mathematik |

| Naturwissenschaften ► Biologie ► Biochemie | |

| Naturwissenschaften ► Biologie ► Ökologie / Naturschutz | |

| Naturwissenschaften ► Chemie ► Analytische Chemie | |

| Naturwissenschaften ► Chemie ► Organische Chemie | |

| Naturwissenschaften ► Chemie ► Technische Chemie | |

| Naturwissenschaften ► Geowissenschaften ► Geologie | |

| Technik ► Bauwesen | |

| Technik ► Elektrotechnik / Energietechnik | |

| Technik ► Lebensmitteltechnologie | |

| Technik ► Maschinenbau | |

| Technik ► Umwelttechnik / Biotechnologie | |

| Weitere Fachgebiete ► Land- / Forstwirtschaft / Fischerei | |

| ISBN-10 | 0-08-086837-1 / 0080868371 |

| ISBN-13 | 978-0-08-086837-0 / 9780080868370 |

| Haben Sie eine Frage zum Produkt? |

Größe: 32,7 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: PDF (Portable Document Format)

Mit einem festen Seitenlayout eignet sich die PDF besonders für Fachbücher mit Spalten, Tabellen und Abbildungen. Eine PDF kann auf fast allen Geräten angezeigt werden, ist aber für kleine Displays (Smartphone, eReader) nur eingeschränkt geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich