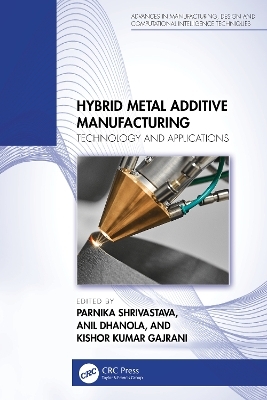

Hybrid Metal Additive Manufacturing

CRC Press (Verlag)

978-1-032-46055-0 (ISBN)

The text presents the latest research and development, technical challenges, and future directions in the field of hybrid metal additive manufacturing. It further discusses the modeling of hybrid additive manufacturing processes for metals, hybrid additive manufacturing of composite materials, and low-carbon hybrid additive manufacturing processes. THIS BOOK: Presents cutting-edge advancements and limitations in hybrid additive manufacturing technologies; Discusses fabrication methods and rapid tooling techniques focusing on metals, composites, and alloys; Highlights the importance of low-carbon additive manufacturing technologies toward achieving sustainability; Emphasizes the challenges and solutions for integrating additive manufacturing and Industry 4.0 to enable rapid manufacturing of customized and tailored products; Covers hybrid additive manufacturing of composite materials and additive manufacturing for fabricating high-hardness components.

The text discusses the recent advancements in additive manufacturing of high-hardness components and covers important engineering materials such as metals, alloys, and composites. It further highlights defects and post-processing of hybrid additive manufacturing components, sustainability solutions for hybrid additive manufacturing processes, and recycling of machining waste into metal powder feedstock. It will serve as an ideal reference text for senior undergraduate and graduate students, and researchers in fields including mechanical engineering, aerospace engineering, manufacturing engineering, and production engineering.

Dr. Parnika Shrivastava is an Assistant Professor in the Department of Mechanical Engineering at the National Institute of Technology, Jalandhar, Punjab, India. Dr. Parnika Shrivastava is currently working as an assistant professor at the Mechanical Engineering Department of the National Institute of Technology Jalandhar (Punjab). She has earned Doctorate and M.Tech. degree in Mechanical Engineering from PDPM, Indian Institute of Information Technology, Design & Manufacturing Jabalpur, Jabalpur, in 2019. She has completed B.Tech. degree (Honors) from Mechanical Engineering Discipline of Engineering College Bikaner (E.C.B), Bikaner, Rajasthan. Her research areas of interest are advanced forming operations, hybrid manufacturing, fracture mechanics, rapid product development technologies, and topology optimization. She has been granted a patent on the “Process of analyzing the effect of preheated microstructure vis-à-vis parameters on the orange peel in incremental sheet forming of AA1050 sheets”. She has authored various research articles in International Journals of repute along with several conference publications and book chapters. She has been recently granted a Core Research Grant funding for undertaking the project “Design and development of an Electrically Assisted Hybrid Double Sided Incremental Forming machine for efficient production of customized biomedical implants with improved surface finish and geometrical accuracy”. She is also the recipient of two national-level awards including the Best Teacher Award 2022 conferred by the Indian Society for Technical Education, New Delhi. Dr. Anil Dhanola is an Assistant Professor in the Department of Mechanical Engineering at the Chandigarh University, Mohali. He completed his M.Tech. with honors in production engineering from Govind Ballabh Pant Institute of Engineering and Technology, Pauri Garhwal in the year 2015. Dr. Anil earned a full-time Ph.D. in Mechanical Engineering from the Guru Jambheshwar University of Science and Technology, Hisar, Haryana in 2021. He has more than five years of experience in teaching and industry. His domains of research include tribology, fiber-based polymer composites, fluid film lubrication, green lubricants, wind turbine tribology and superlubricity. Dr. Anil has published several articles in peer-reviewed international journals and book chapters. Dr. Anil has also presented various articles at national and international conferences. He is also reviewer of various peer-reviewed international journals. Dr. Kishor Kumar Gajrani is an Assistant Professor in the Department of Mechanical Engineering at the Indian Institute of Information Technology, Design and Manufacturing, Kancheepuram, Chennai, India. He has done M. Tech and Ph.D. from the Department of Mechanical Engineering at the Indian Institute of Technology Guwahati. Thereafter, he worked as a post-doctoral researcher at the Indian Institute of Technology Bombay. He has authored/co-authored 45 + international journals and book chapters of repute. He has also edited/co-edited 3 books titled “Advances in Sustainable Machining, Biodegradable Composited for Packaging Applications as well as Sustainable Materials and Manufacturing Technologies”. He was listed in the "World's Top 2 % Scientists" list in the year 2022 released by Stanford University and published by Elsevier. Dr. Gajrani works on the advancement of sustainable machining processes, additive manufacturing, advanced materials, tribology, coatings, green lubricants, and coolants as well as food packaging.

Chapter 1

Hybrid metal additive manufacturing technology

Arun Kumar Bambam, Prameet Vats, Alok Suna, and Kishor Kumar Gajrani

Chapter 2

An overview of wire arc additive manufacturing (WAAM) technique with different alloys in modern manufacturing industries

Tuhina Goshwami, Shatarupa Biswas, Santanu Das, and Manidipto Mukherjee

Chapter 3

Wire-fed arc-based additive manufacturing techniques and their recent advances

Bunty Tomar and Shiva S.

Chapter 4

Joining of metal to polymers by hybrid additive manufacturing methods

Tharmaraj R, Rajesh Jesudoss Hynes N, and Shenbaga Velu P

Chapter 5

A review on heat treatments, microstructure, and mechanical properties of selective laser-melted AISI 316L

Tushar R. Dandekar

Chapter 6

Advancements in integrated additive manufacturing for composite materials: techniques, challenges, case studies, and applications

Praveen Kumar, Palanisamy Sivasubramanian, Pradeepkumar C, Nitin Yadav, and Carlo Santulli

Chapter 7

Hybrid additive manufacturing of composite materials

Shenbaga Velu P, Rajesh Jesudoss Hynes N, and Tharmaraj R

Chapter 8

Printing a sustainable future: how additive manufacturing is revolutionising the fight against plastic waste

Jagdeep Kaur, Atri Rathore, Tarveen Kaur, and Prabal Batra

Chapter 9

Towards a greener future: how additive manufacturing and bio-based materials are saving the environment

Jagdeep Kaur, Sahil Srivastava, Anil Dhanola, and Sachin Moond

Chapter 10

Characterization of titanium feedstock powder prepared by recycling of machining chips using ball milling

Prameet Vats, Arun Kumar Bambam, Kishor Kumar Gajrani, and Avinash Kumar

Chapter 11

Additive manufacturing for Industry 4.0

Francis Luther King M, Robert Singh G, Gopichand A, and Srinivasan V

Chapter 12

Digital twin-driven additive manufacturing: advancements and future prospects

P M Abhilash, Jibin Boban, Afzaal Ahmed, and Xichun Luo

Chapter 13

Additive manufacturing for society

Alex Y, Nidhin Divakaran, and Smita Mohanty

| Erscheinungsdatum | 07.12.2023 |

|---|---|

| Reihe/Serie | Advances in Manufacturing, Design and Computational Intelligence Techniques |

| Zusatzinfo | 7 Tables, black and white; 65 Line drawings, black and white; 15 Halftones, black and white; 63 Illustrations, color; 17 Illustrations, black and white |

| Verlagsort | London |

| Sprache | englisch |

| Maße | 156 x 234 mm |

| Gewicht | 1440 g |

| Themenwelt | Kunst / Musik / Theater ► Design / Innenarchitektur / Mode |

| Technik ► Bauwesen | |

| Technik ► Maschinenbau | |

| Technik ► Umwelttechnik / Biotechnologie | |

| ISBN-10 | 1-032-46055-5 / 1032460555 |

| ISBN-13 | 978-1-032-46055-0 / 9781032460550 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich