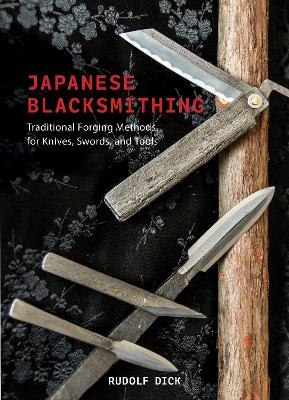

Japanese Blacksmithing

Traditional Forging Methods for Knives, Swords, and Tools

Seiten

2025

Schiffer Publishing Ltd (Verlag)

978-0-7643-6851-6 (ISBN)

Schiffer Publishing Ltd (Verlag)

978-0-7643-6851-6 (ISBN)

- Lieferbar (Termin unbekannt)

- Versandkostenfrei innerhalb Deutschlands

- Auch auf Rechnung

- Verfügbarkeit in der Filiale vor Ort prüfen

- Artikel merken

Discover the blacksmithing techniques used to make 10 traditional Japanese objects, with insights from the artisans and rare glimpses inside their workshops

Discover the blacksmithing techniques used to make 10 traditional Japanese objects with insights from the artisans and rare glimpses inside their workshops.

The art of blacksmithing and steel processing didn't reach Japan until more than 1,000 years after it was developed in the Western world. It is therefore all the more astonishing to see the high culture of forging that developed in the Land of the Rising Sun within a short period of time.

This comprehensive reference book explains the traditional methods used by Japanese tool-, knife-, and swordsmiths and gives the reader a rare and unique look inside their workshops.

In these pages, readers will find

• forging methods and techniques for 10 special products—hammer, chisel, axe, hatchet, gardener's machete, sickle, fish knife, folding knife, straight razor, and Japanese sword;

• more than 150 color photographs that illustrate and explain the techniques used to create classic Japanese forged pieces;

• chapters on Japan's oldest coppersmithing facility and traditional tatara steel smelting; and

• helpful tables that detail the materials, chemistry, elements, and temperatures needed to harden, form, and manipulate the metal being forged.

This is a must-have book, not only for amateur and professional smiths, but also for all admirers of Japanese craft culture.

Discover the blacksmithing techniques used to make 10 traditional Japanese objects with insights from the artisans and rare glimpses inside their workshops.

The art of blacksmithing and steel processing didn't reach Japan until more than 1,000 years after it was developed in the Western world. It is therefore all the more astonishing to see the high culture of forging that developed in the Land of the Rising Sun within a short period of time.

This comprehensive reference book explains the traditional methods used by Japanese tool-, knife-, and swordsmiths and gives the reader a rare and unique look inside their workshops.

In these pages, readers will find

• forging methods and techniques for 10 special products—hammer, chisel, axe, hatchet, gardener's machete, sickle, fish knife, folding knife, straight razor, and Japanese sword;

• more than 150 color photographs that illustrate and explain the techniques used to create classic Japanese forged pieces;

• chapters on Japan's oldest coppersmithing facility and traditional tatara steel smelting; and

• helpful tables that detail the materials, chemistry, elements, and temperatures needed to harden, form, and manipulate the metal being forged.

This is a must-have book, not only for amateur and professional smiths, but also for all admirers of Japanese craft culture.

Dr. Rudolf Dick studied mechanical engineering at the Technical University of Munich and received his doctorate in forming technology. He served as the managing director of Dick GmbH, Fine Tools, and retired from active business life in 2007. He lives in Deggendorf and Munich, Germany. https://rudolfdick.com/

| Erscheinungsdatum | 25.11.2024 |

|---|---|

| Zusatzinfo | 175 color photos |

| Verlagsort | Atglen |

| Sprache | englisch |

| Maße | 165 x 229 mm |

| Gewicht | 45 g |

| Themenwelt | Kunst / Musik / Theater ► Kunstgeschichte / Kunststile |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Kreatives Gestalten | |

| Geisteswissenschaften ► Geschichte ► Regional- / Ländergeschichte | |

| Technik ► Maschinenbau | |

| ISBN-10 | 0-7643-6851-6 / 0764368516 |

| ISBN-13 | 978-0-7643-6851-6 / 9780764368516 |

| Zustand | Neuware |

| Informationen gemäß Produktsicherheitsverordnung (GPSR) | |

| Haben Sie eine Frage zum Produkt? |

Mehr entdecken

aus dem Bereich

aus dem Bereich