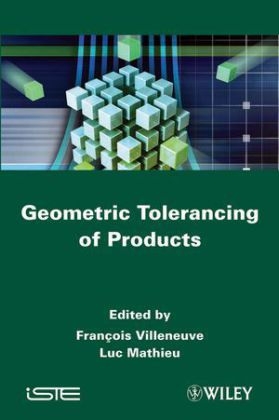

Geometric Tolerancing of Products

ISTE Ltd and John Wiley & Sons Inc (Verlag)

978-1-84821-118-6 (ISBN)

Francois Villeneuve, University of Grenoble, France. , University Paris-Sud 11, France.

PART I. GEOMETRIC TOLERANCING ISSUES 1

Chapter 1. Current and Future Issues in Tolerancing: the GD&T French Research Group (TRG) Contribution 3

Luc MATHIEU and François VILLENEUVE

1.1. Introduction 3

1.2. Presentation of the Tolerancing Resarch Group: objectives and function 4

1.3. Synthesis of the approach and contributions of the group 5

1.4. Research perspectives 13

1.5. Media examples: “centering” and “connecting rod-crank”15

1.6. Conclusion 17

1.7. Bibliography 19

PART II. GEOMETRIC TOLERANCING LANGUAGES 21

Chapter 2. Language of Tolerancing: GeoSpelling 23

Alex BALLU, Jean-Yves DANTAN and Luc MATHIEU

2.1. Introduction 23

2.2. Concept of the GeoSpelling language 24

2.3. Geometric features 26

2.4. Characteristic 29

2.5. Operations 38

2.6. Conditions 43

2.7. Specifications on assemblies – quantifiers 44

2.8. Applications to part specification 45

2.9. Applications to product specifications 48

2.10. Conclusion 51

2.11. Bibliography 52

Chapter 3. Product Model for Tolerancing 55

Denis TEISSANDIER and Jérôme DUFAURE

3.1. Introduction 55

3.2. Objectives and stakes 56

3.3. Proposal for a product model 58

3.4. Benefits of the IPPOP product model 68

3.5. Application on the centering device 73

3.6. Conclusion 84

3.7. Bibliography 84

Chapter 4. Representation of Mechanical Assemblies and Specifications by Graphs 87

Alex BALLU, Luc MATHIEU and Olivier LEGOFF

4.1. Introduction 87

4.2. Components and joints 89

4.3. The requirements, technical conditions and specifications 97

4.4. Manufacturing set-ups 100

4.5. Displacements between situation features and associated loops103

4.6. The key elements 107

4.7. Conclusion 109

4.8. Bibliography 110

Chapter 5. Correspondence between Data Handled by the Graphs and Data Product 111

Denis TEISSANDIER and Jérôme DUFAURE

5.1. Introduction 111

5.2. Correspondence between tolerancing graphs and the product data 112

5.3. Correspondence between manufacturing set-ups and the data product 118

5.4. Conclusion 121

PART III. 3D TOLERANCE STACK-UP 123

Chapter 6. Writing the 3D Chain of Dimensions (Tolerance Stack-Up) in Symbolic Expressions 125

Pierre BOURDET, François THIÉBAUT and Grégory CID

6.1. Introduction 125

6.2. A reminder of the establishment of the unidirectional chain of dimensions by the ∆l method 126

6.3. Establishment in writing of a chain of dimensions in 3D by the method of indeterminates in the case of a rigid body 135

6.4. Consideration of the contact between parts in the mechanisms 142

6.5. Mechanisms composed of flexible parts, joints without gap (or imposed contact) and imposed effort 144

6.6. Conclusion 147

6.7. Bibliography 148

Chapter 7. Tolerance Analysis and Synthesis, Method of Domains 151

Max GIORDANO, Eric PAIREL and Serge SAMPER

7.1. Introduction 151

7.2. Deviation torsor and joint torsor 152

7.3. Equations of loops 155

7.4. Deviation and clearance domains 158

7.5. Representation and properties of the domains 162

7.6. Application to the analysis of simple chains 168

7.7. Case of assemblies with parallel joints 173

7.8. Taking elastic displacements into account 176

7.9. Conclusion 180

7.10. Bibliography 180

Chapter 8. Parametric Specification of Mechanisms 183

Philippe SERRÉ, Alain RIVIÈRE and André CLÉMENT

8.1. Introduction 183

8.2. Problem of the parametric specification of complete and consistent dimensioning 184

8.3. Generation of parametric tolerancing by the differential variation of the specification of dimensioning 188

8.4. Problem of the specification transfer 192

8.5. Expression of parametric tolerancing 193

8.6. Case study 198

8.7. Conclusion 204

8.8. Bibliography 205

PART IV. METHODS AND TOOLS 207

Chapter 9. CLIC: A Method for Geometrical Specification of Products 209

Bernard ANSELMETTI

9.1. Introduction 209

9.2. Input of a tolerancing problem 210

9.3. Part positioning 212

9.4. Tolerancing of positioning surfaces 217

9.5. Generation of functional requirements 221

9.6. Specification synthesis 222

9.7. Tolerance chain result 227

9.8. Tolerance synthesis 234

9.9. Conclusion 238

9.10. Bibliography 238

Chapter 10. MECAmaster: a Tool for Assembly Simulation from Early Design, Industrial Approach 241

Paul CLOZEL and Pierre-Alain RANCE

10.1. Introduction 241

10.2. General principle, 3D tolerance calculation 242

10.3. Application to assembly calculation 245

10.4. From model to parts tolerancing 263

10.5. Statistical tolerancing 268

10.6. Industrial examples 269

10.7. Conclusion 271

10.8. Bibliography 272

PART V. MANUFACTURING TOLERANCING 275

Chapter 11. Geometric Manufacturing Simulation 277

Stéphane TICHADOU and Olivier LEGOFF

11.1. Introduction 277

11.2. Modeling of manufacturing set-up 279

11.3. Approaches to geometric manufacturing simulation 288

11.4. Conclusion 303

11.5. Bibliography 303

Chapter 12. 3D Analysis and Synthesis of Manufacturing Tolerances 305

Frédéric VIGNAT and François VILLENEUVE

12.1. Introduction 305

12.2. Manufacturing transfer, analysis and synthesis in 1D 306

12.3. 3D manufacturing simulation model (MMP) 314

12.4. From the manufacturing process to the MMP 317

12.5. 3D analysis of the functional tolerances 323

12.6. 3D synthesis of manufacturing tolerances 329

12.7. Conclusion 338

12.8. Bibliography 339

PART VI. UNCERTAINTIES AND METROLOGY 341

Chapter 13. Uncertainties in Tolerance Analysis and Specification Checking 343

Jean-Marc LINARES and Jean Michel SPRAUEL

13.1. Introduction 343

13.2. Proposal for a statistical model of real surfaces 343

13.3. Applications in metrology 354

13.4. Application to tolerance analysis 367

13.5. Conclusion 373

13.6. Bibliography 374

List of Authors 375

Index 377

| Verlagsort | London |

|---|---|

| Sprache | englisch |

| Maße | 163 x 241 mm |

| Gewicht | 721 g |

| Einbandart | gebunden |

| Themenwelt | Kunst / Musik / Theater ► Malerei / Plastik |

| Sachbuch/Ratgeber ► Freizeit / Hobby ► Malen / Zeichnen | |

| Technik ► Maschinenbau | |

| ISBN-10 | 1-84821-118-X / 184821118X |

| ISBN-13 | 978-1-84821-118-6 / 9781848211186 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich