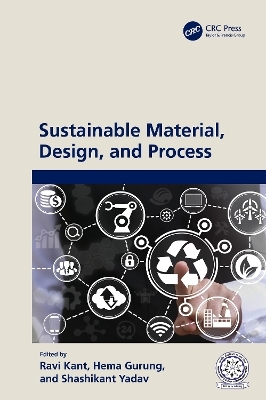

Sustainable Material, Design, and Process

CRC Press (Verlag)

978-1-032-15052-9 (ISBN)

- Lieferbar (Termin unbekannt)

- Versandkostenfrei innerhalb Deutschlands

- Auch auf Rechnung

- Verfügbarkeit in der Filiale vor Ort prüfen

- Artikel merken

This text emphasizes the importance of sustainable material, design, and manufacturing processes, and how the needs are changing day by day. It comprehensively covers important topics including material recycling, optimal utilization of resources, green materials, biocomposites, clean and green synthesis, stable material properties, utilization of renewable energy sources, ergonomic design, and sustainable design. The text examines the design process, manufacturing, and upscaling of next-generation materials and their application in diverse industries. The text is primarily written for graduate students and academic researchers in the fields of manufacturing engineering, materials science, mechanical engineering, and environmental engineering.

Presents an in-depth understanding of the progress of the need for new innovative and next-generation materials.

Discusses biocomposites and green materials for eco-friendly products in a comprehensive manner.

Explores recycling techniques of materials for sustainable manufacturing.

Presents conceptual framework of sustainable product development.

Covers important topics such as process optimization, renewable energy, and 3D printing in detail.

The text discusses the designing process of these new materials, manufacturing, and upscaling of these materials along with their selection for industrial applications. It further focuses on improving surface homogeneity in nanoparticle scattering during dip coating for stable and efficient wettability during oil/water separation. It will serve as an ideal reference text for graduate students and academic researchers in the fields of manufacturing engineering, materials science, mechanical engineering, and environmental engineering.

Dr. Ravi Kant is an Assistant Professor in the Department of Mechanical Engineering at Indian Institute of Technology Ropar, India. He received his Bachelor degree in Mechanical Engineering from Maharshi Dayanand University, Rohtak (Haryana, India). He completed his M. Tech. from Department of Mechanical Engineering at Indian Institute of Technology (IIT) Guwahati, India with specialization in "Computer Assisted Manufacturing". He worked on the Investigation on Formability of Adhesively Bonded Sheets during his M. Tech. project. He also obtained his doctorate from IIT Guwahati in the field of laser forming process. His research interests include Laser transmission welding; Hybrid machining; Laser forming; Cold spray coatings; Additive manufacturing, Hybrid joining and Sustainable materials. He has completed many research projects and consultancy works in these research areas. He has contributed around 80 research articles in peer-reviewed journals, conferences, and edited books. He has edited one book titled "Simulations for design and manufacturing" published by Springer Singapore. He has also guest edited five special issues in reputed journals. He has developed and taught advanced courses like Modern manufacturing processes; Sustainability science and technology; Analysis of casting, forming and joining processes; Advanced welding technology; Micromanufacturing; Manufacturing, etc. He has also conducted various international conferences, workshops, symposiums, Colloquiums, and faculty development programs in the field of advanced manufacturing technology. Dr. Hema Gurung is an independent researcher in the field of Robotics. She obtained her bachelor degree from Kalyani University (West Bengal, India) in Electronics and Instrumentation Engineering. She completed her M. Tech. in Mechatronics from IIEST (Indian Institute of Engineering and Science Technology, Shibpur, India) and received her Ph.D. from the Department of Mechanical Engineering at Indian Institute of Technology Guwahati, India in the field of Robotics. She had worked in Hanbat National University, South Korea and Thapar University, India. Her research work includes experimental analysis, numerical simulation, optimization, control systems, state estimator, robotics, smart sensors and actuators. She has published a good number of research articles in international journals, conferences and edited books. Currently she is working at the application of smart sensors and actuators in Industry 4.0. Dr. Shashikant Yadav is an Assistant Professor in the Department of Chemical Engineering at Dr B R Ambedkar National Institute of Technology Jalandhar, India. He received his Bachelor degree in Chemical Engineering from Deenbandhu Chhotu Ram University of Science and Technology, Murthal Sonipat (Haryana, India). He completed his M. Tech. from Department of Chemical Engineering at Indian Institute of Technology (IIT) Roorkee, India with specialization in "Computer Aided Process Plant Design". He completed his Ph.D. from Department of Chemical Engineering at Indian Institute of Technology (IIT) Bombay, India on the topic "Carbon sequestration by carbon dioxide in mineral slurries and industrial waste". His research interests include CO2 Sequestration, Multiphase Reactions, Mineral Carbonation, Waste Utilization and Management, Analytical, Numerical and Soft—Computing Modeling and Optimization of Reaction Processes, Social and Economic Engineering, Edible films and coatings.

Chapter 1: Modelling the Ceramic Membrane Surface Properties to minimize Clusters during Nanoparticle Coating by Jet-spray for Efficient Wettability during Oil-Water Separation

T.G. Maome, P. B. Sob, A. A. Alugongo and T. B. Tengen

Chapter 2: Fabrication of biopolymer composite film derived from agro-waste possessing antioxidant properties

Malvika Sharma, Preeti Beniwal, Amrit Pal Toor

Chapter3: DESIGN, DEVELOPMENT AND ANALYSIS OF AN IMPROVED TRICYCLE

Partha Pratim Dutta, Polash P. Dutta, Mrinmoy G. Baruah

Chapter 4: Potential Bio composites for Food Packaging: A Green and sustainable Approach

Raghavendra Subramanya, Arjun.S, Dheeraj KG, Sarvepally S Gokul, Rishikesh M R, Amol S Pawar

Chapter 5: Thermal Performance Studies of a V-Type Baffle Absorber Plate Used in a Solar Air Heater

Partha Pratim Dutta, Harjyoti Das

Chapter 6: Design, fabrication, and testing of FSW fixture for conventional milling machine

Boddepalli Durga Rao, Siddhant Palai, Rashmi Rekha Sahoo, Sritam Pattnayak, Anjan Kumar Mishra

Chapter 7: Numerical Analysis of Fin Heat Transfer in Radiators Using Simulation Software Comsol Multiphysics 5.5

Shivashree Sharma, Saroj Yadav

Chapter 8: An environment friendly emerging technique for machining: Minimum Quantity Lubrication

Roshan Lal Virdi, Amrit Pal, Sukhpal Singh Chatha, Hazoor Singh Sidhu

Chapter 9: EFFECT OF SURFACE TOPOGRAPHY AND ROUGHNESS ON THE WETTING CHARACTERISTICS OF AN INDIGENOUSLY DEVELOPED GREEN CUTTING FLUID (GCF)

Vimal Edachery, Sindhu Ravi, Aliya F. Badiuddin, Abel Tomy,

Suvin P. S., Satish V. Kailas

Chapter 10: Ergonomic design analysis of Analogue micrometer screw gauge

Sangeeta Pandit, Neel P Padia

| Erscheinungsdatum | 06.09.2023 |

|---|---|

| Zusatzinfo | 62 Line drawings, black and white; 56 Halftones, black and white; 33 Illustrations, color; 85 Illustrations, black and white |

| Verlagsort | London |

| Sprache | englisch |

| Maße | 156 x 234 mm |

| Themenwelt | Kunst / Musik / Theater ► Design / Innenarchitektur / Mode |

| Technik ► Bauwesen | |

| Technik ► Maschinenbau | |

| ISBN-10 | 1-032-15052-1 / 1032150521 |

| ISBN-13 | 978-1-032-15052-9 / 9781032150529 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich