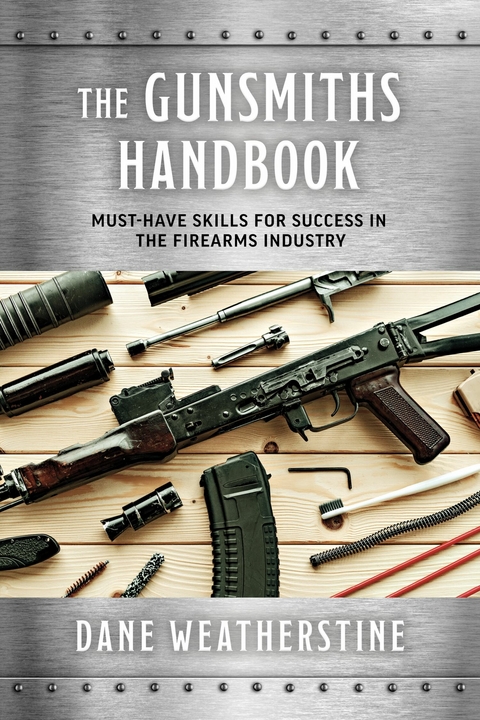

Gunsmiths Handbook (eBook)

184 Seiten

Bookbaby (Verlag)

979-8-3509-5248-3 (ISBN)

Dane Weatherstine, was born and raised in Baltimore Md. He was not raised around firearms because his mother had always been anti-gun and his father was not in the picture. His mother held on to this irrational fear that a firearm will kill someone because in Baltimore, killings were a daily occurrence. It took many years for her to understand that this was not the fault of the firearm but rather the person. Nevertheless, the home remained gun free. After graduating high school and working a number of jobs, Dane stepped into an Army recruiter's office and made the decision to join the Infantry and fight in Iraq. He was sent to Fort Benning for OSUT (One Station Unit Training) where he was first introduced to the M4 rifle and later the M249 SAW (Squad Automatic Weapon). It was on Sand Hill that he realized how much he loved working with the M249 machine gun so when he got his first set of orders sending him to what was then Fort Hood Texas, he landed a position as a machine gunner with the 1st Battalion, 8th Calvary Regiment, 2nd Brigade Combat Team. As an active-duty Infantrymen, it did not take long to deploy into Iraq with this new team. Many missions later Dane was medically discharged because of the injuries sustained while fighting there. Following that, Dane decided to start attending college using the GI Bill. During this time Dane needed work and long story short, he got a job at a local gun range as an RSO (Range Safety Officer). He started work there as a customer advocate and in a few years became the training manager and lead trainer. He loved working for this company but as luck had it, he also loved a woman who worked with the company named Julia. She was educated and fun to be around so against company policy he asked her out. A few more years later, Dane and Julia were getting married, and it was Julia's turn to serve in the US Army. Life has a way of bringing you back full circle and this was no exception because Julia's first duty station was, in fact, the same Fort Hood Texas Dane had served with many years prior. Having relocated to Texas during the covid shutdowns, finding work was difficult . Most places were forced to shut down and the places that could stay open were well staffed and not hiring. Dane started firing off his resume and a few odd jobs later he found himself working at another gun range. Texas had labeled gun ranges as essential businesses and were allowed to continue operations during Covid. It was at this new gun range Dane became a state licensed firearms instructor, NRA and USCCA instructor, and completed his Associates in Firearms Technology with the Sonoran Desert Institute. After many years of watching people struggle to solve their firearms related problems, Dane decided to author this book.

This extensive book caters to a wide audience, including experienced gunsmiths seeking to enhance their skills and knowledge, as well as gun enthusiasts eager to learn more about the craftsmanship behind firearms. It delves deep into the intricacies of gun maintenance, repair, and customization, providing step-by-step instructions and insightful tips to help readers master the art of gunsmithing. Moreover, this comprehensive guide goes beyond just technical skills by offering a detailed roadmap for those interested in starting their own gunsmithing business. It covers essential aspects such as creating a business plan, obtaining the necessary permits and certifications, setting up a workspace, acquiring tools and equipment, sourcing materials, and developing effective marketing strategies. The book also delves into crucial considerations for running a gunsmithing business at its peak efficiency, including maintaining high-quality standards, ensuring customer satisfaction, managing finances, handling legal and regulatory issues, and adapting to market trends. By combining practical guidance with industry expertise, this book serves as an invaluable resource for anyone looking to not only excel in gunsmithing but also thrive as a successful entrepreneur in the firearms industry.

Section Two:

Gunsmithing Basic Knowledge

The purpose of a test fire when working with firearms.

There may be many reasons for a test fire on a firearm. The first being the customer claims something is not working correctly with their firearm. In this case you may need to test fire to see the actual malfunction they were talking about in order to better understand the issue and find the best way to resolve it. In other cases, a test fire may be part of ensuring a firearm you built yourself actually functions. With an FFL that allows the manufacturing of firearms you can purchase all the parts you want for a build and assemble the firearm from scratch. This, however, means that you should test fire before selling the firearm to ensure the product being put out for sale is a functioning one.

As someone who has spent a number of years working for live fire facilities, I have seen countless firearms I was unfamiliar with and was then asked to clean, diagnose, or fire them. This can be a little unsettling at times especially when it is a much older firearm worth a fair bit of money. In such cases I would usually admit to the customer that I am new to this make or model and that it would take me some time to do the research to complete the task the correct way. Doing research is one of the best ways to make an unfamiliar firearm safe to test fire. The firearm may be in great working order but if you the operator have no idea how it works it may yield unsafe results. Now if the customer is ok with someone who just admitted to knowing little about their firearm to complete the task, then do as you promised and take the time to do it right. At the very least, if you did make a mistake then you don’t look like someone claiming to be a professional but having no clue.

The first thing you must know before attempting to disassemble or inspect a firearm.

The first things I need to know about a firearm before attempting to disassemble it is who makes it, is it loaded and how does the safety work. Knowing the make and model points me in the right direction and takes some guess work out. Knowing if it is loaded or not is important for safety and knowing if the firearms have a safety and how it works goes with that. After that it would be important to figure out how the make and model is broken down, even if just for a quick field strip for cleaning. Most Handguns have a takedown lever located above the trigger and trigger guard, but this will change from brand to brand and model to model. A fair number of rifles use machine screws that need to be removed before disassembly and most shotguns require the use of a punch to remove pins for a breakdown. No matter what the firearm, step one is safety and step two is learning the method in which to begin your disassembly.

Bluing and Browning, both hot and cold methods.

Both cold bluing with Perma Blue solution and Browning using Laurel Mountain solution give you the fastest results and do not require the user to heat the metals to work. If you cannot afford an expensive setup and do not have days to get the work done, then these options may be the best choice. This is not to say they yield the best results or that they do not require a lot of work to be done right. It is only to say that they get results faster than the other methods. Laurel Mountain solution is to be applied every three hours and can get satisfactory results in about four coats depending on the finish you desire. Cold bluing can be applied to the surface every few minutes and can get satisfactory results in 6-8 coats. Both require some surface preparation that can be done with a few pieces of fine grit sandpaper. You will also need an applicator swab or cotton ball used to apply the solution and they require steel wool to re-prep the surface in between coatings. Other than that, no real equipment is needed to perform the task. These chemicals can be dangerous if inhaled or if they get on your skin so be sure to use gloves when applying and be sure you are in a well-ventilated area.

Hot bluing and your basic browning do require some equipment to get the job done right and you will need specific chemicals to achieve the desired results. When hot bluing it helps to have the right tanks that utilize burners underneath. This gives the user comfort in knowing they are getting an even heat throughout. I have seen people use tanks on bricks and a single burner underneath and this usually will not yield consistent results if just the middle of the tank reaches the correct temperature. When rust bluing or “Browning” firearms the process seems safer in terms of the fumes let off like when hot bluing. Simply apply your browning solution directly on the parts and hang them in a damp box. This is needed to speed up the rusting process required to achieve the desired finish. Once a light coating of surface rust develops remove it from the damp box and boil the parts in distilled water for about 20 minutes. This helps turn that red rust into a black surface coating. Clean it up with a wire brush or some steel wool (free of oil) and repeat the process about 7-8 times for the best results. Both hot bluing and browning can off gas some pretty bad stuff so please be sure that when attempting either process you are in a well-ventilated area and wearing the proper personal protective equipment like gloves and a respirator. If you want a deep black finish to the firearm, I recommend browning the parts because when hot bluing with Nitrate bluing salts you will get a blue tint in the finish.

Do you believe you will be able to complete the detail-strip of your firearm?

I would be able to detail strip the Glock pistol completely because I have all of the tools and training needed to do so safely and correctly. There are still a ton of firearms I would not be able to say this about because it would be impossible to know every step for every firearm that walks through the door at the range I currently work out of. On top of that, some firearms have firearm specific tools needed in order to completely break them down and I do not own those tools yet because I have not been faced with those issues yet.

Having the Glock Armorer Certification helps me with regard to the knowledge and confidence needed to fully disassemble and inspect Glock firearms. Before I took this training course, I had never broken a Glock all the way down because I was not sure what I was looking at and I was afraid I might break something. Sitting with a certified instructor who walked me through the steps helped me build confidence and since then I have no idea how many Glock pistols I have worked on. My advice is to seek qualified instructors and training as often as possible and become a well-rounded gunsmith.

Attempting to troubleshoot a customer’s weapon without being able to fix the parts.

Though I believe it is necessary to be able to fix fasteners and other small parts, I also believe it is reasonable to begin the trouble shooting process even if you are unable to fix the part causing the problem. Step one is always clearing the firearm and if the customer was claiming it will not chamber a round and you find out it was because they were loading them backwards, then the problem is solved. You did not need the ability to fix small parts to solve this problem. Most of the time you will not have the small part that has broken on hand anyway so why not begin the process to at least identify the issue component. Now if the part in question is not fully broken and you are able to fix the part to get the firearm working again then awesome, but you will never get to that point in the process until you make the attempt. Recently I was given a 1911 with a removable front sight. The client was getting older and wanted Tru Glow sights to be put on so he could see it better. This is usually a few minutes of work with double that going into making sure they are lined up correctly. However, the front sight I was provided was not made for that make and model firearm. It was my ability to use files correctly to reshape the sight to fit that allowed me to see the job to completion. However, there is no shame in turning down work because you are not comfortable attempting something you’re uncomfortable or unconfident with. I did it for years before I had the confidence to try more stuff.

The differences between standard and metric measurement systems.

Some differences between the metric system and the standard system are their units of measurement. For example, regarding length the metric system uses millimeters, centimeters, and meters while the standard system uses inches, feet, and yards. When talking about the difference between units of measurement regarding mass the metric system uses kilograms and grams while the standard uses pounds and ounces. Some might argue that one is better than the other, but most people are not taught both and present biased opinions.

I believe the metric system is the preferred method of measurement across the world today because that’s what is being taught to everyone since birth in most regions. We didn’t grow up in the time when these decisions were being made and we could contribute to the outcome of these decisions. Instead, everyone is taught from grade school one unit of measure or the other and almost never get taught both. So, when you think metric is the standard, then it gets taught to the next generation and so on. I don’t think one is preferred over the other, I just think people are taught one OR the other and that becomes THEIR standard.

Finally, I do not believe the US should...

| Erscheint lt. Verlag | 30.6.2024 |

|---|---|

| Sprache | englisch |

| Themenwelt | Wirtschaft |

| ISBN-13 | 979-8-3509-5248-3 / 9798350952483 |

| Haben Sie eine Frage zum Produkt? |

Größe: 3,8 MB

Digital Rights Management: ohne DRM

Dieses eBook enthält kein DRM oder Kopierschutz. Eine Weitergabe an Dritte ist jedoch rechtlich nicht zulässig, weil Sie beim Kauf nur die Rechte an der persönlichen Nutzung erwerben.

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen dafür die kostenlose Software Adobe Digital Editions.

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen dafür eine kostenlose App.

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich