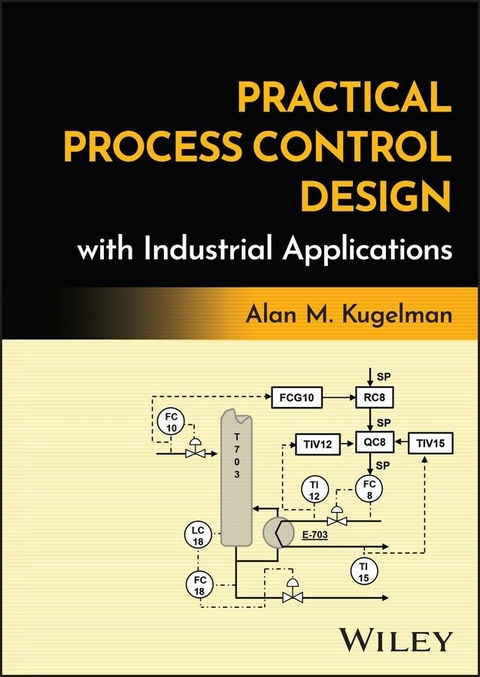

Practical Process Control Design with Industrial Applications (eBook)

640 Seiten

Wiley (Verlag)

978-1-394-24650-2 (ISBN)

Practical guidance on how to apply process control fundamentals to solve real-world control problems

Practical Process Control Design with Industrial Applications presents process control essentials and control strategy design fundamentals for modern-day DCS work environments. It uses a unique instructional approach-a process analysis and process understanding framework that enables readers to better understand and more effectively use process control fundamentals. Process analysis, operating objectives, and business drivers guide the identification of control objectives and facilitate control strategy designs of realistic control applications for real-world unit operations.

Filling a gap in the literature, coverage includes:

- Merging process analysis, process understanding, and real-world plant operations with process control essentials and design fundamentals

- Detailed discussion of real-world design issues and realistic process-specific control strategies

- Methods used to ensure acceptable control performance continues when various 'what if' issues arise

- How process control design fundamentals are applied in important unit-specific control strategies

- How best to apply specific control attributes (control direction), control options (PID proportional action), standard DCS functionality (algorithms and/or function blocks), and corporate or site standards (input signal validation) to develop control strategies that achieve control objectives with acceptable control performance.

Practical Process Control Design with Industrial Applications is an essential reference for control engineers and process engineers who support process control activities in an operating plant, DCS vendor control application specialists, and EPC company project engineers who support process control activities in capital projects.

Alan M. Kugelman, PhD, has more than 40 years' experience in process control application design and implementation in capital projects, DCS migration projects and DCS modernization projects. Working for ExxonMobil Research and Engineering Company (Florham Park, NJ, later in Fairfax, Va.), he developed his process control applications design and implementation expertise during three onsite assignments at ExxonMobil sites in Europe and Japan. He then supported ExxonMobil control applications activities, in both refineries and chemical plants worldwide, from central engineering offices in Brussels, Florham Park, and Fairfax. He developed, and taught company-administered control application training courses to site control engineers worldwide.

Practical guidance on how to apply process control fundamentals to solve real-world control problems Practical Process Control Design with Industrial Applications presents process control essentials and control strategy design fundamentals for modern-day DCS work environments. It uses a unique instructional approach a process analysis and process understanding framework that enables readers to better understand and more effectively use process control fundamentals. Process analysis, operating objectives, and business drivers guide the identification of control objectives and facilitate control strategy designs of realistic control applications for real-world unit operations. Filling a gap in the literature, coverage includes: Merging process analysis, process understanding, and real-world plant operations with process control essentials and design fundamentalsDetailed discussion of real-world design issues and realistic process-specific control strategies Methods used to ensure acceptable control performance continues when various what if issues ariseHow process control design fundamentals are applied in important unit-specific control strategiesHow best to apply specific control attributes (control direction), control options (PID proportional action), standard DCS functionality (algorithms and/or function blocks), and corporate or site standards (input signal validation) to develop control strategies that achieve control objectives with acceptable control performance. Practical Process Control Design with Industrial Applications is an essential reference for control engineers and process engineers who support process control activities in an operating plant, DCS vendor control application specialists, and EPC company project engineers who support process control activities in capital projects.

Preface

Practical Process Control Design with Industrial Applications presents process control essentials and control strategy design fundamentals that are applicable to modern-day digital control system (DCS) work environments. To provide a realistic framework to better understand and use these fundamentals more effectively, many authentic industrial control application designs are presented and discussed. To make the book’s content more beneficial to control engineers and process engineers who support in-plant process control activities, process control practices and design fundamentals are applied in a wide variety of unit operations.

The book’s control strategy design discussions are intended to be independent of specific DCSs. Instead, the focus is on the control strategy’s cascade structure, its inherent functionality, and its relationship to unit operating objectives. No matter the DCS, the use of standard DCS functionality, i.e., standard algorithms and/or function blocks, is emphasized. Given the author’s wide-ranging experiences over the years with Honeywell hardware and software, the DCS functionality assumed to be standard and the functionality assumed to be nonstandard mirror that Honeywell experience. However, references to the DCS control environment, DCS functionality, and control strategy structures and configuration have been kept as generic as possible to allow these basic concepts to be understood by practicing control engineers working in other DCS environments. Where user-provided custom code and/or configuration is required to furnish nonstandard functionality, descriptions of the logic and calculations are provided, but coding and configuration details, which would obviously be DCS specific, are not.

The book’s target audience is control engineers and process engineers who support process control activities in an operating plant, and project engineers who support process control activities in capital projects and DCS modernization projects. This includes operating company, DCS vendor, and engineering, procurement, and construction (EPC) company personnel. For the target audience, the book provides these major benefits:

- A better understanding of control strategy design fundamentals. The many realistic control strategy designs presented for a wide variety of unit operations provide a practical framework for understanding essential process control fundamentals.

- Methods that increase control strategy robustness. Methods are presented to manage numerous “what if” design issues that increase control strategy robustness and ensure acceptable control performance continues.

- Effective control strategy designs for a variety of common unit operations. Unit-specific control strategy designs for many common, industrial important process units are presented and discussed.

The book is not intended to be a university level process control textbook. That need is filled by many excellent texts that present control fundamentals with underlying theory and mathematical details. However, clearly missing from the current mix of process control textbooks are discussions of control strategy designs that link realistic process unit operating objectives to the strategy’s control objectives. Also absent is how control design fundamentals are applied in typical modern-day DCS work environments. Thus, this book’s focus is on control strategy designs that emphasize the use of standard DCS functionality and achieve control objectives in industrially important process units.

With this focus, the important roles of process analysis and process understanding are emphasized when operating and control objectives are identified and control strategies designed. Because process understanding is so essential to a control strategy’s design, a P&ID type drawing of the process unit’s configuration is included for each control application and is an integral part of the application’s discussion. A second drawing shows (i) the control strategy’s conceptual design, e.g., the components that provide the required control functionality to achieve the control objectives and (ii) the control cascade’s structure, e.g., how the control components are logically ordered and linked from ultimate secondary to ultimate primary.

The process control essentials, control strategy design fundamentals, and realistic control applications presented and discussed make the book a prime process control reference. The book also provides abundant source material for operating company in-house process control training courses, and DCS vendor and EPC in-house or customer-focused training courses. And, although not in the book’s target audience, if a chemical engineering faculty member wants to incorporate realistic control strategies into an undergraduate or graduate level process control course, the book provides a wide variety of control applications that illustrate how process control fundamentals are applied to develop real-world solutions to real-world control problems.

The book’s use of process analysis and process understanding to help identify operating and control objectives and design control strategies is a unique, otherwise unavailable instructional approach to process control. The book applies process control design fundamentals in these important unit-specific control strategies:

- Reactor feed drum and surge drum inventory controls

- Tower and reactor feed preheat control strategies implemented in highly heat-integrated units

- Tower, fractionator, and reactor control strategies that reduce energy consumption

- Fired heater firing and combustion control strategies

- Distillation tower product quality controls and fractionation management, with and without a sidestream

- Primary and main fractionator product quality control strategies that must run in a multivariable and interactive operating environment

- Fixed bed catalytic reactor conversion control strategies that manage temperature effects, catalyst deactivation, and reactor feed/product heat integrations

In addition to traditional process control topics, in-depth discussions of the following real-world design issues, covered superficially (if at all) in other process control textbooks, are included and emphasized. And where appropriate, an enhanced understanding of the issue’s role in control strategy design is provided by realistic control strategy examples.

- The discreet PID control algorithm’s controlled variable (CV) and manipulated variable (MV) engineering range and percentage of range conversions, its initialization, its configuration options, and option choices for specific control needs

- The relationships among an ultimate secondary’s PID control direction, its control output characteristic, its A/O block’s output direction, a valve characteristic, and the valve’s failure mode

- A ratio controller’s configuration options, its initialization, how it provides steady-state and dynamic ratio feedforward control, and how it manages unavailable and invalid feedforward inputs

- Ensuring bumpless cascade initialization – with no final control element (e.g., valve) movement on the initialization pass, and how initialization status is transmitted upward in a cascade from any secondary to the ultimate primary

- Ensuring control strategies are commissioned and decommissioned bumplessly

- Controller and cascade wind-up, wind-up protection, wind-up direction and its resolution, and how wind-up status is transmitted upward in a cascade from any secondary to the ultimate primary

- Commissioning and decommissioning feedforward control without affecting feedback control

- Validating unreliable measured and calculated inputs used in a control calculation

- Ensuring feedback control is unaffected when feedforward control inputs are declared invalid or become unavailable, and when inputs return valid or become available again

- Ensuring control strategy robustness when any control input is declared invalid or returns valid

Note that there can be more than one control strategy design that in principle can achieve the control objectives that are identified. This can be true even if the preferred design is developed using recommended approaches – careful process analysis, real-time operations monitoring, analysis of operational history, and/or discussions with process technical and operations personnel. A conclusive judgment on a preferred design’s suitability can be made only after its design features are built/loaded in the DCS and carefully tested, first offline, and then online interfaced to process operations. Its online performance must be monitored, its control performance evaluated, and there must be confirmation that the control objectives are achieved.

The specific, realistic control strategy design examples presented and discussed in this book have not undergone direct offline or online DCS testing. However, extensive in-plant experiences over many years confirm their acceptability and suitability for the unit configurations considered. But appropriate alternative conventional advanced control designs may exist. Therefore, when a control strategy’s design is discussed, and performance uncertainties are identified, other approaches that may improve performance are described, e.g., the use of model-based control to better manage dead times.

At times, more advanced controls may be appropriate, e.g., DMC to better manage multivariable...

| Erscheint lt. Verlag | 22.7.2024 |

|---|---|

| Sprache | englisch |

| Themenwelt | Naturwissenschaften ► Chemie |

| Technik | |

| ISBN-10 | 1-394-24650-1 / 1394246501 |

| ISBN-13 | 978-1-394-24650-2 / 9781394246502 |

| Haben Sie eine Frage zum Produkt? |

Größe: 34,3 MB

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich