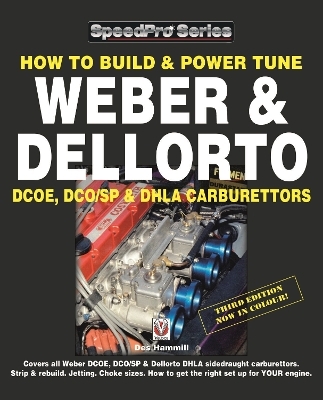

How to Build & Power Tune Weber & Dellorto Dcoe, Dco/Sp & Dhla Carburettors 3rd Edition

Veloce (Verlag)

978-1-84584-959-7 (ISBN)

Des Hammill is a professional engineer with huge experience of building successful and reliable racing engines and solving the problems associated with all aspects of high performance applications. Des has written many of Veloce's SpeedPro series books.

(c) Des Hammill & Veloce Publishing

CHAPTER 1: KNOW YOUR CARBURETOR - STRIPDOWN & INSPECTION 14

Know your carburetor - major

components 14

Chokes and auxiliary venturis 14

Idle mixture adjusting screws 15

Main jet, emulsion tube & air

corrector 15

Progression hole inspection

covers 16

Idle jet 17

Accelerator pump jets 18

Accelerator pump 19

Floats 20

Needle & seat 22

Stripdown - general advice 22

Cleaning components 22

Fuel enrichment devices

- special note 24

Stripdown procedure 25

Fuel enrichment device

- blocking off discharge holes

(Weber only) 26

Inspecting components for wear

and damage 27

Weber & Dellorto 27

Weber only 27

Dellorto only 27

Difficult procedures 27

Clearing passageways 27

Throttle butterfly, spindle &

bearings - maintenance,

removal & refitting 28

Removing damaged threaded components 34

Removing jammed chokes and

auxiliary venturis 35

CHAPTER 2: REBUILDING 37

Needle valve & seat (Dellorto) 37

Floats & fulcrum pin (Dellorto) 37

Fulcrum pin - checking 37

Floats - checking 37

Floats & pin - fitting 38

Float level - setting (Dellorto) 38

Top cover (Dellorto) 39

Body components (Dellorto) 39

Needle valve & seat (Weber) 44

Floats & fulcrum pin (Weber) 44

Fulcrum pin - checking 44

--------------------------------------------------------------------------------

Floats - checking 44

Floats and fulcrum pin - fitting 45

Float level - setting (Weber) 45

Top cover (Weber) 45

Body components (Weber) 49

CHAPTER 3: FUEL

MANAGEMENT, AIR

FILTERS & RAM TUBES 54

Fuel filters 54

Fuel lines (pipes) & fittings 54

Air filters 55

Ram tubes (stacks) 56

Fuel pressure 56

CHAPTER 4: CHOOSING THE

COMPONENTS FOR YOUR

CARBURETOR/S 58

Components - initial selection 58

Choke size versus carburetor

size 58

Choke size - selecting 59

Idle jet - selecting 61

Idle jet codes (Weber) 61

Idle jet codes (Dellorto) 62

Idle jet & air bleed component

- selection 62

Idle mixture and progression

holes 63

Idle screw adjustment

procedure 64

Main jet - selection 64

Emulsion tube - selection 64

Air corrector - selection 65

Auxiliary venturi - selection 66

Accelerator pump jet

- selection 68

Accelerator pump intake/

discharge valve 69

Needle valve - selection 69

CHAPTER 5: MANIFOLD

PREPARATION &

CARBURETOR FITTING 70

Intake manifold - checking &

preparation 70

The importance of stud

alignment 70

Carburetor - checking fit 71

Anti-vibration mountings 73

--------------------------------------------------------------------------------

Carburetor/s - fitting to

manifold 74

CHAPTER 6: TESTING

& SET-UP 75

Idle speed 75

Fuel level & needle valve

operation - checking 75

Throttle - initial adjustment

and synchronization 76

Throttle arm fit 76

Throttle - initial setting

(single carburetor) 76

Throttle - initial set-up &

synchronization (multiple

carburetors) 76

Idle mixture - initial

adjustment 76

Throttle (linked throttle arm

type) - final synchronization 79

Throttle (bar & pushrod type)

- final synchronization 81

Full throttle check 82

Idle jet alteration (fuel

component) 82

Ignition timing - general 83

Idle jets/air bleeds - final

selection 84

Weber 85

Dellorto 86

Idle mixture screws

- final setting 87

Accelerator pump jets

- final selection 88

CHAPTER 7: TESTING & PROBLEM SOLVING 90

Rolling road (dyno) testing

procedure 90

Track testing procedure 91

Solving problems

- low to mid-range rpm 91

Solving problems

- high rpm 92

Webers - fuel leakage from

fuel enrichment device 92

Webers - adapting for off-road

applications 93

Return springs 94

Tuning by exhaust gas co% 94

Maintenance 95

--------------------------------------------------------------------------------

CHAPTER 8: JETTING/SETTING

EXAMPLES 96

BMC/Rover A-Series 1275cc

engine (Weber) 96

Ford 'Pinto' 2000cc SOHC

standard engine (Weber) 97

Ford 'Pinto' 2000cc SOHC

standard engine (Dellorto) 97

Vauxhall 2000cc 16v engine

(Dellorto) 97

Ford RS 2000cc SOHC Escort 98

Ford Sierra Cosworth 2000cc

(naturally aspirated)(Weber) 98

BMC B-Series 1900cc MGB

engine (Weber) 98

Toyota 4A-GE 1600cc 16-valve

MR2 engine (Weber) 98

MG 1940cc alloy 8 port

Magnette engine 98

Ford 1600cc Crossflow engine

(Weber) 99

Jaguar XK 3.8 litre engine

(Dellorto) 99

Ford 1628cc Crossflow engine

(Weber) 99

Ford 'Pinto' 2100cc engine fitted

to Formula 27 sports car

(Dellorto) 99

2000cc Ford Sierra Cosworth racing engine (Dellorto) 99

Ford 1760cc Crossflow engine

(Dellorto) 100

BMC/Rover 1275cc A-series engine

(Dellorto) 100

DETAILS OF COMPLEMENTARY

SPEEDPRO BOOKS 101-108

GLOSSARY OF TERMS 109

INDEX 111-112

(c) Des Hammill & Veloce Publishing

| Erscheinungsdatum | 13.07.2018 |

|---|---|

| Reihe/Serie | Speedpro |

| Sprache | englisch |

| Maße | 207 x 250 mm |

| Gewicht | 484 g |

| Themenwelt | Sachbuch/Ratgeber ► Beruf / Finanzen / Recht / Wirtschaft |

| Natur / Technik ► Fahrzeuge / Flugzeuge / Schiffe ► Auto / Motorrad | |

| Technik ► Fahrzeugbau / Schiffbau | |

| ISBN-10 | 1-84584-959-0 / 1845849590 |

| ISBN-13 | 978-1-84584-959-7 / 9781845849597 |

| Zustand | Neuware |

| Haben Sie eine Frage zum Produkt? |

aus dem Bereich