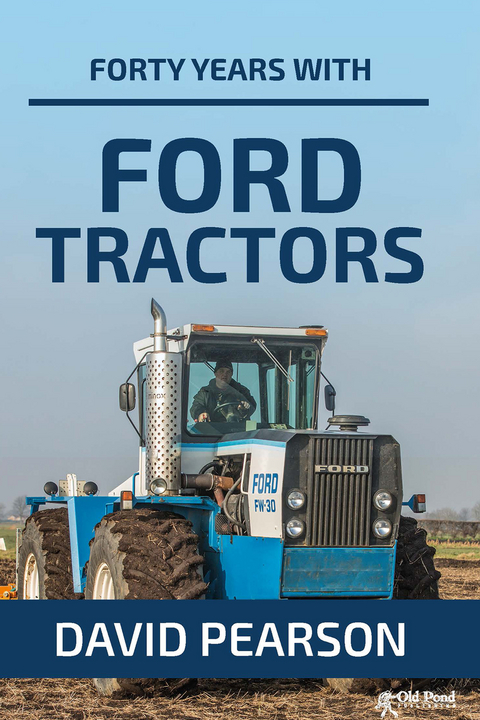

Forty Years with Ford Tractors (eBook)

134 Seiten

Old Pond Books (Verlag)

978-1-910456-71-2 (ISBN)

David W. Pearson and Ron Bommarito both live near the Ludwig historic mining district of Nevada and are experienced, long-time students of mining and collectors of mining artifacts. They each have examined thousands of items in public and private collections and watched the evolving market carefully.

David W. Pearson and Ron Bommarito both live near the Ludwig historic mining district of Nevada and are experienced, long-time students of mining and collectors of mining artifacts. They each have examined thousands of items in public and private collections and watched the evolving market carefully.

When I was a small boy of eight, I discovered a farm at the end of the road along which we lived. Olders Farm, in Angmering, West Sussex, was 50 acres of mostly grassland, with two acres of fodder beet for the dairy unit of 20 Ayrshire cows. Fascinated by its comings and goings, I asked the farmer if he would allow me to help with mucking out and feeding. So began my fascination with farming.

With the promise that one day I would be paid, probably half a crown, I was allowed to take on certain farm tasks. I loved the work, and would happily spend every day of my school holidays there. Our only form of power was a Shire horse, which pulled the cart that carried the manure out to the field, but neither this nor my father’s warning against my choice of industry could put me off – I wanted to work in farming.

As my youth progressed, I continued spending every spare moment on the farm. One Saturday, when I was about 16, I was invited to a wedding at the local golf club, but didn’t plan a late evening – I had promised to look in on a sow due to farrow later that night. The best laid plans often go awry, though, and while at the reception I was introduced to Martinis. In my innocence, I had no idea they were neat alcohol, and while I did get back to check on the pig, all I can remember was waking up at 6 o’clock the following morning with a very sore head, surrounded by the sow and 21 piglets.

Two years later, I can recall my father telling me that if I was ever to get married and start a family, I would have to find a job that paid more than the £4 a week to which I had finally graduated. With my agricultural interests in mind, he suggested I write to Massey Ferguson and to Ford, the two biggest names in tractors at that time.

December 1954 saw me taking the trip up to Coventry for an interview at the MF factory. To my surprise, I was offered a job on the spot, and was told I could start work the following September. But that was nine months away – and I couldn’t afford to wait that long.

My next trip was to Dagenham, home at that time of Ford’s UK tractor manufacturing business, where the world-famous Fordson Major was produced. Somehow I got an appointment to see Harry Power, the head of the Fordson manufacturing operations, and father of Harry and John, who both later worked for the company. I explained to Mr Power that all I wanted to do was drive tractors, whereupon he told me that I would have to learn how to make them before I could do that!

Again, I was lucky enough to be offered a job on the spot, and this time it was to start almost immediately. I gratefully accepted, and was told I could begin work on the tractor line in D Building at 7.15am on Monday, 10 January 1955, on a salary of six pounds and three shillings a week. The parents of my father’s secretary lived in a house in Upminster, which was a train and bus journey away from the plant, and initially looked as if it would provide handy lodgings. However, I omitted to tell them about the 7.15am start time, which meant I had to creep around when rising at 5.30am to catch the train to Dagenham Heathway and then a bus to the plant. I found this very embarrassing and soon found new digs with people who were more used to getting up at this ungodly hour.

On my first day at the plant, I found the line foreman and introduced myself. Ten minutes later I was straight in the thick of things, having been sent to D building, where engines were tested below ground in the dynamometer test beds. Each test bed had two engines, one running and one waiting its turn. There were ten bays, with two engines and one man in each bay, and each engine was run for one hour, in heat of almost 90°F – outside there was 10in of snow. If an engine was deemed to be running OK, it then started on its journey down the line to becoming a Fordson Major, the key Ford tractor model of the period.

I was told to dress in a white coat – although everyone else seemed to be wearing blue overalls. The engine tester, who was supposed to be supervising me, ignored me until, after two hours of watching, I asked if I could help connect up the inlet and exhaust, bolt the engine to the dynamometer and turn on the water for cooling. He looked at me in amazement but agreed, and after an hour he realised I had got the hang of it and sat down to read his paper. We were now mates. When I later returned from lunch he had a pair of blue overalls for me, well soaked in oil. He then removed my white coat and placed it in the bin, informing me I wouldn’t be needing it any more. I later learned that white coats were worn by inspectors and a change of clothes made me ‘one of the boys’ instead of one of ‘them’. This was undoubtedly a very important day in my life and never to be forgotten. I soon knew the first name of every man on the line, and to them I became ‘Dave’.

After two weeks on the dynamometers, I moved on. Every other Monday morning I got a new job in a new location. By week three, I was repairing the engines that hadn’t performed correctly on the dyno test. Slowly but surely I built up the engines and gearboxes, assembled rear transmissions and finally, at the end of the year, reached the end of the line – the repair floor. This is where tractors with problems or parts missing were repaired and approved for shipment.

Tractors going for export did not have batteries fitted, to prevent theft during shipping, so in order to start them batteries on trolleys were connected to the tractors’ terminals. To start the tractor, the throttle was fully opened, the starter depressed, and the cable then connected from the battery. We were always short of space, and on one occasion there were three Majors lined up nose to tail. If I had read the red tag that one day had been fixed to a particular tractor, I would have known it was seized in first gear and I wouldn’t have tried to start it. As a result we now had three tractors all needing new front hoods and bonnets! My mate on the repair floor, Alf, rushed over, removed the warning tag and complained to the foreman that I could have been killed …

Just as I was wondering what I would be doing the following week, a man I hadn’t seen before came across to tell me that next Monday I should report to Mudlands Farm at Rainham, four miles away, better known as the field test site. All modifications to existing tractors were tested here, and prototype tractors started their life at Mudlands before being sent out to work on farms in the local area, which comprised very heavy land adjacent to the River Thames.

At the time I arrived, the engineers had been doing some re-engineering exercises on the Major’s crown wheel and pinion to try to reduce production costs. Testing involved doing figures of eight, turning left with the left brake on and then vice versa. However, the new reduced-cost crown wheel and pinion seldom lasted long enough to get the tractor out of the shed, and we were changing four or five a day! In the end, the need for reliability won the day and we kept the original tried-and-tested arrangement.

As the tractors were on test 24 hours a day, everyone had to do some night work. On the edge of the River Thames where the test track was situated, large piles of soil had been dumped many years previously during the building of the London Underground, and it was quite a spooky place. One night driving round the track pulling a weighted sledge, I got a tap on the shoulder and turned to see a bald man with a stocking over his head. I have to admit I was terrified – until I realised it was a mate doing the same job as me who’d got bored and decided to pull a prank!

The manager of the test site was a wonderful man named George Smale, and I later worked at Ford with his son, Bob. We had a big shed that represented desert working conditions, with a floor of cement dust that also came to cover the walls and ceiling. One day a young lad was working in there and I was persuaded to throw a half-shaft on to the roof to dislodge the cement – as you can imagine, the air became choked with dust and it was impossible to see a thing. A full five minutes passed before he crawled out, choking and spluttering. It wasn’t until then that the colleagues who’d goaded me into playing this prank told me the boy’s father was the plant manager! Fortunately, no one else ever knew who the culprit was …

I had been promised that I would soon be driving the prototype of the new Dexta tractor, named not after the breed of little black cattle, but as in dextrous – skilful and able. In March 1956 a message came to me to cancel my digs and collect all my gear. Along with two charming Irishmen – one, Ted Lonergan, who became a very good friend – I was to then go with two new prototype Dextas and a little grey Ferguson for comparison to our test site, which was to be the Elveden Estate in Suffolk. The new task would see me back in farming for the next two years.

The digs Ford had chosen for us were in a pub sited just 6ft from the main railway line, and we were shown a double bed and told we were all sleeping in it! Before I had time to refuse, the two Irishmen had said they were not having it and walked out. Eventually, we found better lodgings at the Bell at Mildenhall, which was to be our home for the next two years. Daily expenses were 16 shillings – about 75 pence – which paid for our bed, breakfast, a packed lunch and an evening meal. We had jugs and bowls in the room for...

| Erscheint lt. Verlag | 1.10.2019 |

|---|---|

| Verlagsort | Mount Joy |

| Sprache | englisch |

| Themenwelt | Natur / Technik ► Fahrzeuge / Flugzeuge / Schiffe ► Allgemeines / Lexika |

| Natur / Technik ► Fahrzeuge / Flugzeuge / Schiffe ► Nutzfahrzeuge | |

| Naturwissenschaften ► Biologie | |

| Technik | |

| Wirtschaft | |

| Weitere Fachgebiete ► Land- / Forstwirtschaft / Fischerei | |

| Schlagworte | articulated tractors • British farming • classic tractors • farm history • farm tractors • Transport |

| ISBN-10 | 1-910456-71-3 / 1910456713 |

| ISBN-13 | 978-1-910456-71-2 / 9781910456712 |

| Haben Sie eine Frage zum Produkt? |

Kopierschutz: Adobe-DRM

Adobe-DRM ist ein Kopierschutz, der das eBook vor Mißbrauch schützen soll. Dabei wird das eBook bereits beim Download auf Ihre persönliche Adobe-ID autorisiert. Lesen können Sie das eBook dann nur auf den Geräten, welche ebenfalls auf Ihre Adobe-ID registriert sind.

Details zum Adobe-DRM

Dateiformat: EPUB (Electronic Publication)

EPUB ist ein offener Standard für eBooks und eignet sich besonders zur Darstellung von Belletristik und Sachbüchern. Der Fließtext wird dynamisch an die Display- und Schriftgröße angepasst. Auch für mobile Lesegeräte ist EPUB daher gut geeignet.

Systemvoraussetzungen:

PC/Mac: Mit einem PC oder Mac können Sie dieses eBook lesen. Sie benötigen eine

eReader: Dieses eBook kann mit (fast) allen eBook-Readern gelesen werden. Mit dem amazon-Kindle ist es aber nicht kompatibel.

Smartphone/Tablet: Egal ob Apple oder Android, dieses eBook können Sie lesen. Sie benötigen eine

Geräteliste und zusätzliche Hinweise

Buying eBooks from abroad

For tax law reasons we can sell eBooks just within Germany and Switzerland. Regrettably we cannot fulfill eBook-orders from other countries.

aus dem Bereich